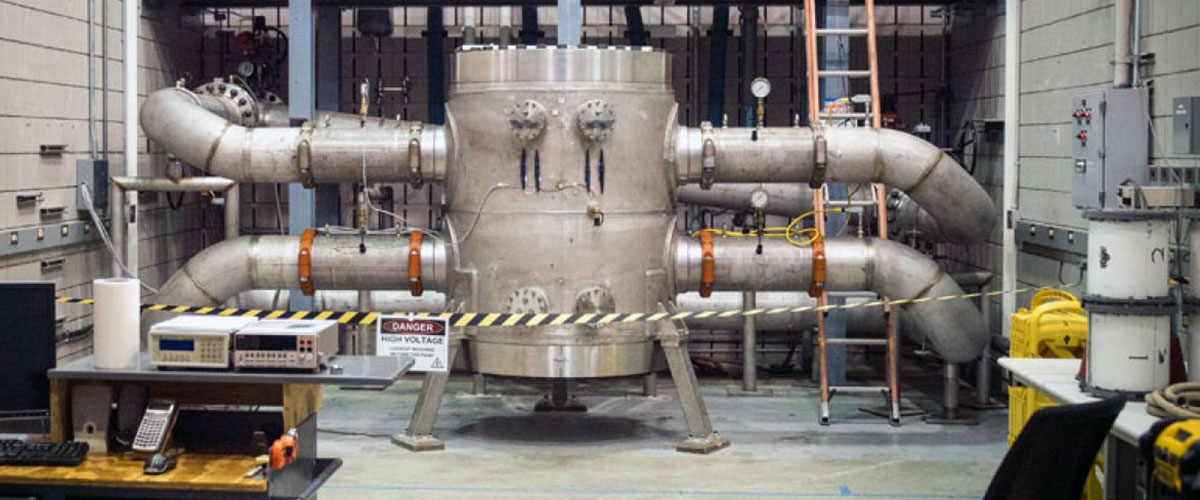

Dozens of researchers within the lab's Magnet Science and Technology department and Applied Superconductivity Center will bring their unique expertise in materials research, magnet design and technology development to this new project. The MagLab’s demonstrated successes in magnet research and development include two recent breakthroughs in HTS technology: a 32-tesla all-superconducting magnet that was designed, built and reached full field at the MagLab in December 2017 and a 14.5 tesla test coil that reached a world record 45.5 tesla field strength inside a 31-tesla resistive magnet.

"Magnets are only as good as the materials and technologies in which they are built," said Mark Bird, director of the Magnet Science and Technology division at the National MagLab. "A magnet like this can only be achieved at the National MagLab where we are leading a revolution in understanding and leveraging high-temperature superconductors."

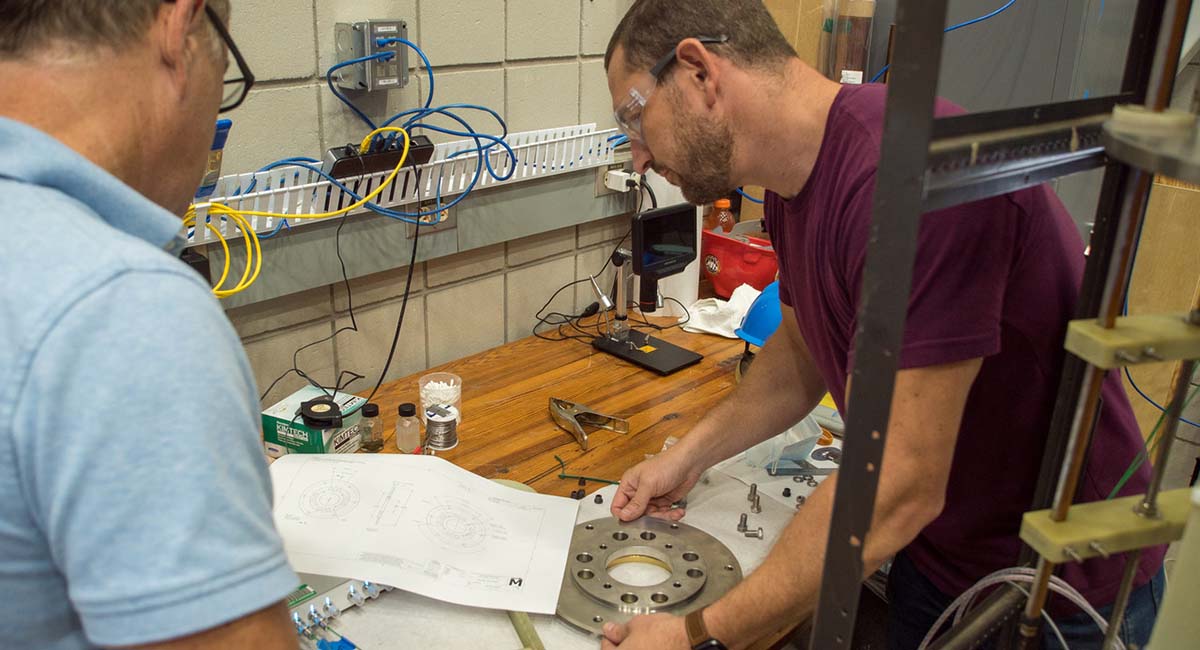

The 40T team includes a diverse mix of engineers, technicians, machinists, researchers and other experts from across the lab.

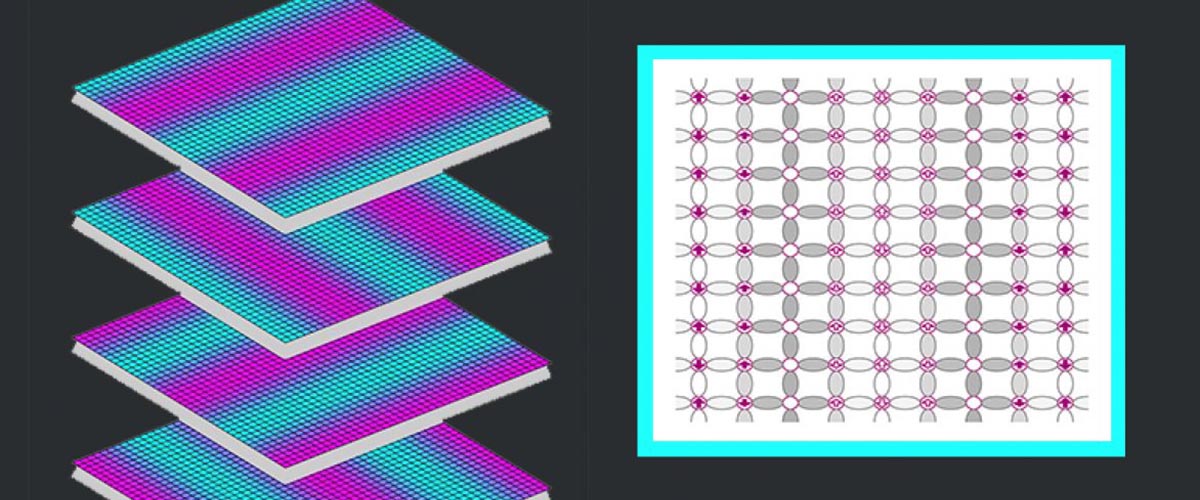

For the final design, MagLab scientists and engineers are considering two different magnet technologies using the high-temperature superconductor known as “rare earth barium copper oxide” or REBCO. The two design strategies take different approaches to address inconsistency in the performance of the REBCO tape. One design uses multiple REBCO tapes in parallel, while the other involves applying a resistive insulation to the tape. The team will develop test coils to advance our understanding of screening currents, stress, and quench protection —each one a component of the myriad technical arcana that must be mastered for the future magnet to be successful.

After additional testing and characterization work, MagLab engineers will complete a final design that will describe in complete detail how a 40T superconducting magnet should be constructed, including the cost and schedule for construction.

"The National High Magnetic Field Laboratory's extraordinary work over the past few decades is evident by the fact that they continue to attract support from the National Science Foundation and others to take us even further in magnet development,” said Interim Vice President for Research Laurel Fulkerson. “We are proud of the work they have already done and will continue to do as they develop a design for the 40T magnet."

The grant funds design work through 2026 and is part of the NSF's Mid-scale Research Infrastructure 1 Program (Mid-scale RI-1), special funding that supports the design efforts for compelling projects that meet a scientific need and enable US researchers to remain competitive in a global research environment.

"U.S. researchers need cutting-edge tools to stay at the forefront of science and technology," said NSF Director Sethuraman Panchanathan. "NSF is committed to filling this mid-scale space in the American scientific research infrastructure by investing in research facilities and instrumentation that advance next-generation discoveries."

Success at this stage will lay the groundwork for a future proposal that, if successful, would fund the construction of the 40T magnet and is an important stepping-stone on the route to a future 60T hybrid magnet, one of the most challenging future magnets proposed in national reports on high magnetic field science.