Advanced Conductor Technologies

Boulder, CO

The Applied Superconductivity Center and the Magnet Science and Technology division of the Magnet Lab are collaborating with Advanced Conductor Technologies on the development and testing of Coated Conductor Stranded Cable (CCSC), using multi-layer spiraling tapes around a core, for magnet applications. Danko van der Laan, director of the company and associated with NIST/University of Colorado Boulder, is developing compact cables based on REBCO coated conductors, a high temperature superconductor. The ongoing collaboration resulted in the first measurements ever of HTS cables at low temperature and high magnetic field (4 K and 20 T in Cell 4).

Advanced Magnet Lab, Inc.

Palm Bay, FL

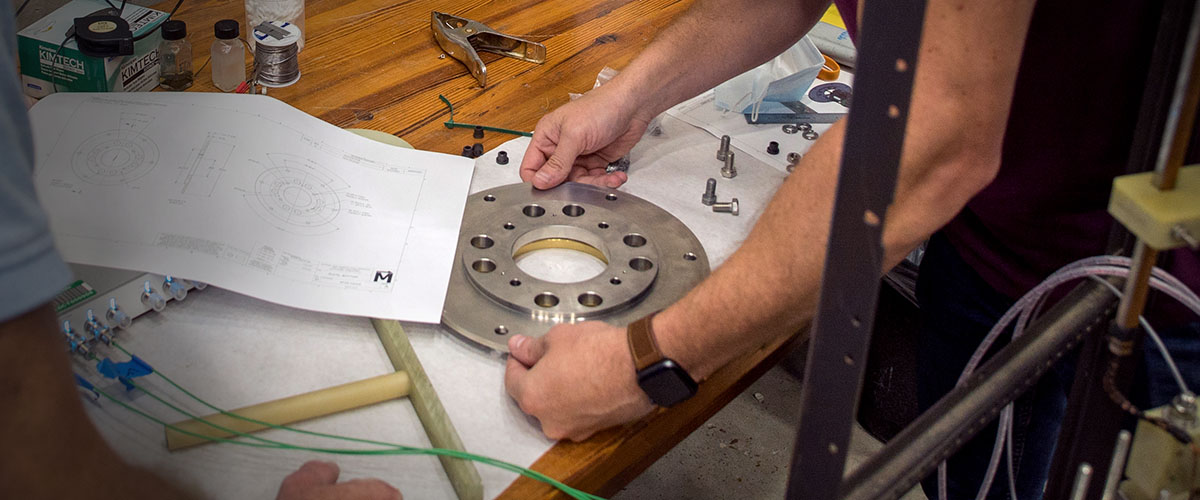

Engineers from the NHMFL are collaborating with Advanced Magnet Lab, Inc. to produce the innovative field-correction shims required to decrease spatial and temporal field disturbances in the Series-Connected Hybrid (SCH). Advanced Magnet Lab has provided the precision fabrication processes required to produce these innovative shims for the first-of-a-kind SCH magnet system that will produce 1 ppm field homogeneity at 36 T.

Contact: Thomas Painter.

Danfoss Turbocor Inc.

Tallahassee, FL

Danfoss Turbocor Inc. is a company specializing in compressors, particularly the totally oil-free compressors. The compressors are specifically designed for the heating, ventilation, air conditioning and refrigeration (HVACR) industry and need high performance soft and hard magnet materials. The company and the laboratory started a joint research project on selection, characterization, and development of permanent magnet materials for high performance and environmentally friendly compressors.

Contact: Ke Han.

Faculty of Material Science and Engineering

Kunming University of Science and Technology, China

The collaboration between the Kunming University and the Magnet Lab is related to the magnetic field impact on phase transformation in steels. A professor from Kunming University was in the Maglab as a visiting scientist for one year to do the research. The collaboration is a continuous effort.

Contact: Ke Han.

Helmholtz Zentrum Berlin

Berlin, Germany

The MagLab has partnered with the Helmholtz Zentrum Berlin (HZB) to develop the highest field magnet worldwide for neutron scattering at HZB. In March 2007, HZB (formerly the Hahn-Meitner Institute) signed an agreement with Florida State University Magnet Research and Development Inc. The magnet is intended to provide 25 T on-axis using 4.4 megawatts of DC power and have upstream and downstream scattering angles of 30 degrees. The present record field for such a configuration is 17 T. Five external design reviews have been held with an international committee of reviewers. Fabrication of the magnet is underway: The superconducting strand has been delivered and cabled and jacketed, the cryostat has been fabricated, winding of the superconducting coil is complete, joints have been fabricated, reaction of the coil to form the superconductor is complete, impregnation of the CICC coil is underway, design of the resistive insert coils is complete and fabrication of them is starting. In the summer of 2013 the cold-mass should ship to Italy where the cryostat will be assembled around it prior to transport to Berlin.

Contact: Mark Bird.

High Performance Magnetics (HPM)

Tallahassee, FL

HPM is a spin-off from the Magnet Lab’s Magnet Science & Technology Division and is involved in the USDOE ITER program. The Cable-in-Conduit-Conductor (CICC) technology used successfully in the NHMFL has led to the development of a state-of-the-art CICC jacketing production line. HPM collaborates with the Magnet Lab to develop test methods and processes that are mutually beneficial for the advancement of CICC technology.

Callaghan Innovations

Lower Hutt, New Zealand

The Applied Superconductivity Center and the Magnet Science and Technology division of the Magnet Lab are collaborating with researchers at New Zealand’s Industrial Research Limited on the testing of Roebel-style cables based on REBCO coated conductors, a high temperature superconductor. Testing of a 15-strand cable with transposed 5 mm wide strands is in preparation. Roebel-style cables represent one of three viable concepts for REBCO coated conductor cables suitable for high field magnets.

Institute of Metal Research

Chinese Academy of Sciences, Shenyang, China

The collaboration between the Institute of Metal Research and the Magnet Lab is related to the characterization of stainless steels and other structural materials for high field magnets. The materials are mainly stainless steel 316LN and maraging steels with high mechanical strength.

Contact: Ke Han.

International Thermonuclear Experimental Reactor (ITER)

US-ITER Project Office, Oak Ridge National Laboratory (ORNL) Oak Ridge, TN

The United States is part of an exciting international collaboration to demonstrate the feasibility of an experimental fusion reactor that is under construction in France. The MS&T’s Mechanical Properties Lab is the US-ITER primary materials research and qualification laboratory supporting the US effort. The Tokamak machine consists of three types of very large complex superconducting magnets that all utilize Cable-in-Conduit Conductors as the main structural components. Another important component for stress management of the Central Solenoid is a massive CS pre-compression structure (Tie Plates). The conduit and tie plate alloys, and their welds are being studied and characterized here to ensure their performance and reliability. The funding for this research is provided by US-DOE, US-ITER Project Office at ORNL.

Thomas Jefferson National Accelerator Facility

Newport News, VA

Large-grain Nb has become a viable alternative to fine-grain Nb for the fabrication of superconducting radio-frequency cavities. NHMFL collaborated with engineers at J-Lab to evaluate the effect of thermal processing and grain size on the mechanical properties of Nb. The mechanical properties evaluation was carried out at MS&T’s Mechanical Properties Lab.

Key Laboratory of Electromagnetic Processing of Materials

Northeastern University, Shenyang, China

The collaboration between the Northeastern University and the Magnet Lab is related to the magnetic field impact on fabrication of high strength conductors. A professor from Northeastern University was in the Maglab as a visiting scientist for one year to do the research. The collaboration is a continuous effort and another professor will be in the Maglab in 2013. A MagLab scientist will visit Northeastern University.

Contact: Ke Han.

Lawrence Berkeley Laboratory

Accelerator and Fusion Research, Berkeley, CA

The Applied Superconductivity Center and the Magnet Science and Technology division of the Magnet Lab are collaborating with researchers at the Berkeley National Laboratory on the testing of Roebel-style cables based on REBCO coated conductors, a high temperature superconductor. Testing of a 10-strand cable with transposed 2 mm wide strands is in preparation. Roebel-style cables represent one of three viable concepts for REBCO coated conductor cables suitable for high field magnets.

Mevion Medical Systems

Littleton, MA

Mevion is a pioneer in the development of proton radiation therapy systems for the non-invasive treatment of cancer. The center of the systems is the proton accelerator that utilizes low temperature superconductors. NHMFL provide engineering support to Mevion by assisting in qualification testing of full-scale high current superconductors in background fields at low temperatures. The tests require NHMFL’s unique test facility designed for tests of large conductors in a 12T split solenoid superconducting magnet system.

University of Science and Technology Beijing

Department of Materials Science and Engineering, Beijing, China

The collaboration between the University of Science and Technology Beijing and the Magnet Lab is related to the thermodynamic calculations of the multi-elements and multiphase systems. Currently, efforts are focused on understanding interstitial elements impact on the precipitation in steels for high field magnets.