When most people think of magnets, they think of the cute vacation mementos that secure lists and pix to a fridge. This leads to the first misconception tour guides at magnet labs tackle when showing the public around their facilities: Research magnets aren't like those small, permanent magnets. Rather, they're enormous electromagnets made of entirely different materials that generate a very high field when you pump lots of current through them.

But, occasionally, researchers do put permanent magnets inside our huge electromagnets to learn more about them, and that is what one company from Texas recently did with a special material it is developing.

Miha Zakotnik

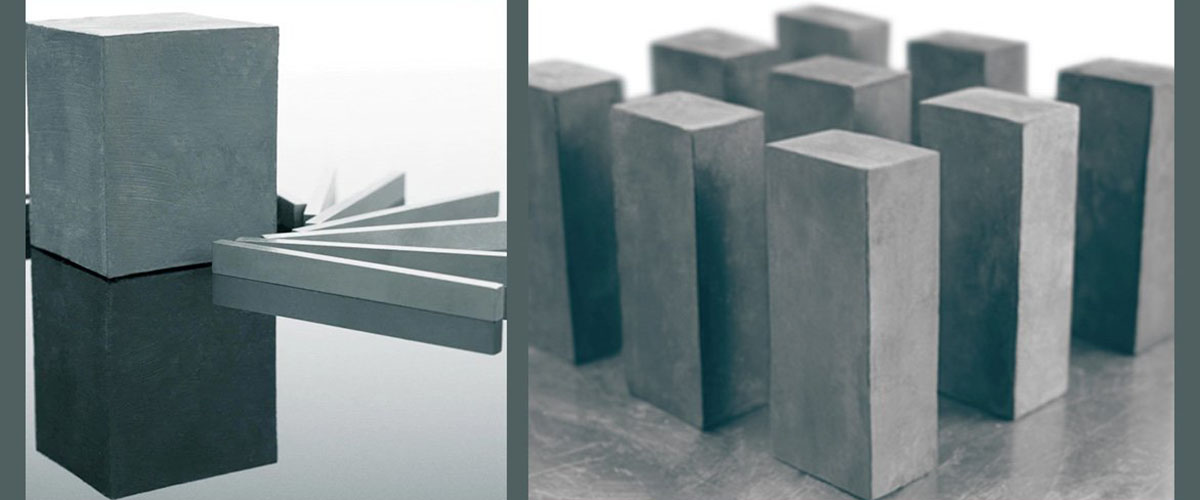

Scientists from Urban Mining Company (UMC) recently visited the National High Magnetic Field Laboratory to test samples of the neodymium iron boride magnets (also referred to as NdFeB, or neo magnets) that they manufacture at their facility near Austin using magnets recovered from recycled electronic devices.

Why recycle old magnets? There's a high demand and low supply for neodymium, a rare earth element that, when mixed with iron and boron, makes a strongly magnetic alloy used in everything from hard-disk drives to electric motors to smartphone speakers. Most of the world's neodymium is mined in China, and the extraction process takes a toll on the environment.

So UMC harvests neo magnets from obsolete products, grinds them up, and uses the powder to make new neo magnets, according to their own special recipe.

How do their products stack up? It depends, explained Miha Zakotnik, chief technology officer and chief operating officer of UMC, which was cited as a company to watch by Fortune magazine's "2019 Change the World List."

"Magnets are engineered products," Zakotnik said. "Each of them is unique, tailored for the application. It's a very complex thing to make."

Scientists in Japan hold the world record for neo magnets in terms of the amount of work they can do (measured in kilojoule per cubic meter), explained Zakotnik. But that is just one measure of performance: Those magnets don't necessarily perform well in high-heat environments, a niche that UMC is targeting with its special manufacturing process.

"When we start to become interesting is motor applications," such as cars and planes, Zakotnik said. "Those environments are up to 240 degrees Celsius (464 degrees Fahrenheit)."

Another type of rare earth magnet, samarium cobalt, has historically been used in high-temperature environments. But neo magnets are stronger, so if they could be engineered to take the heat, they could offer higher performance.

Zakotnik knew that, in conditions such as high heat, UMC's recycled magnets performed better than both used and new neo magnets. But he needed to understand why, in part by better understanding magnetic properties like remanence (the magnetization left behind after an external magnetic field is removed) and coercivity (the material’s ability to withstand an external magnetic field without becoming demagnetized).

Although Zakotnik had studied his products using special microscopes, he had never tried putting his little permanent magnets inside big electromagnets.

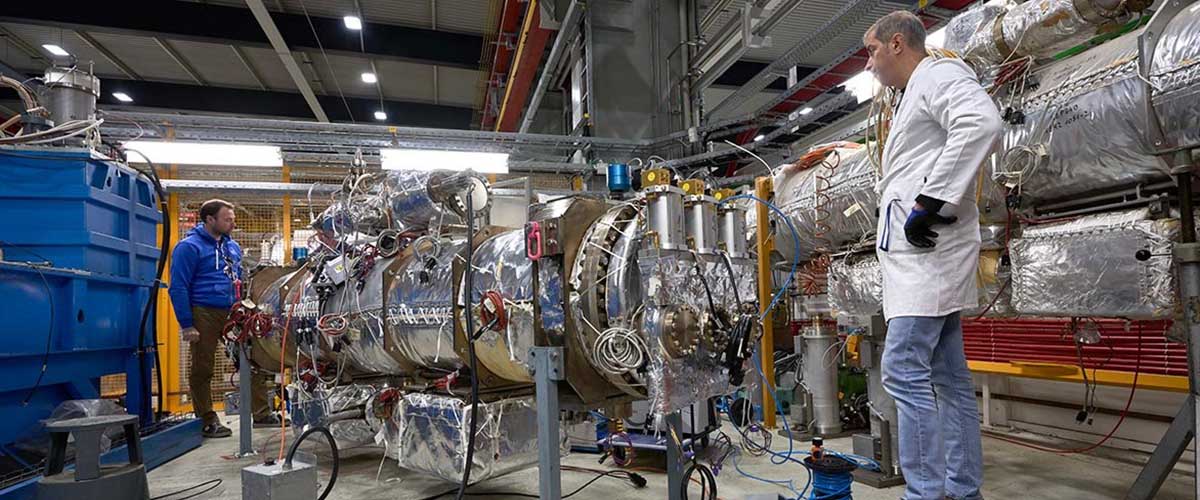

"In order to do this characterization of materials, you must have access to something like this," Zakotnik said of the MagLab, where he used a 16- tesla x Tesla, or T, is a unit of magnetic field strength; a strong refrigerator magnet is .01 tesla, and a typical MRI machine is 1.5 to 3 tesla. The MagLab's strongest persistent magnet has a field of 45 teslas. magnet to make his measurements.

Although the scientists are still interpreting the data, they are excited about what they have seen so far. "We can already see a different picture than what was known before in our field," Zakotnik said.

Those findings are just the beginning; Zakotnik said he has already put in a request to do experiments using a MagLab instrument that is twice as powerful as the first.

Story by Kristen Coyne