Helium is big news lately, and for the most part, the news isn’t good. The global dwindling of this nonrenewable, lighter-than-air resource has been underlined by the government’s 1996 decision to liquidate its reserves by 2015 and to privatize the industry — a move that’s already had a global impact on prices, worried hospitals that use liquid helium for MRI, and has some scientists calling for a ban on (gasp!) party balloons. The MagLab is a major helium customer and, with the construction of a helium-recovery system, is poised for major helium conservation (and major savings).

The ongoing project, which began in 2006, met its two key goals: to better serve the supply needs of the lab’s scientific community, and as more magnets are built, to position the lab to grow. Of course, the cost savings don’t hurt either.

“Last year, a million dollars worth of helium gas left the building and went into the atmosphere. Whether it came though the recovery system and vented, or came out of leaky pipes, it may as well have been dollar bills,” said DC Facilities and Instrumentation Director Scott Hannahs. “This year will transform that.”

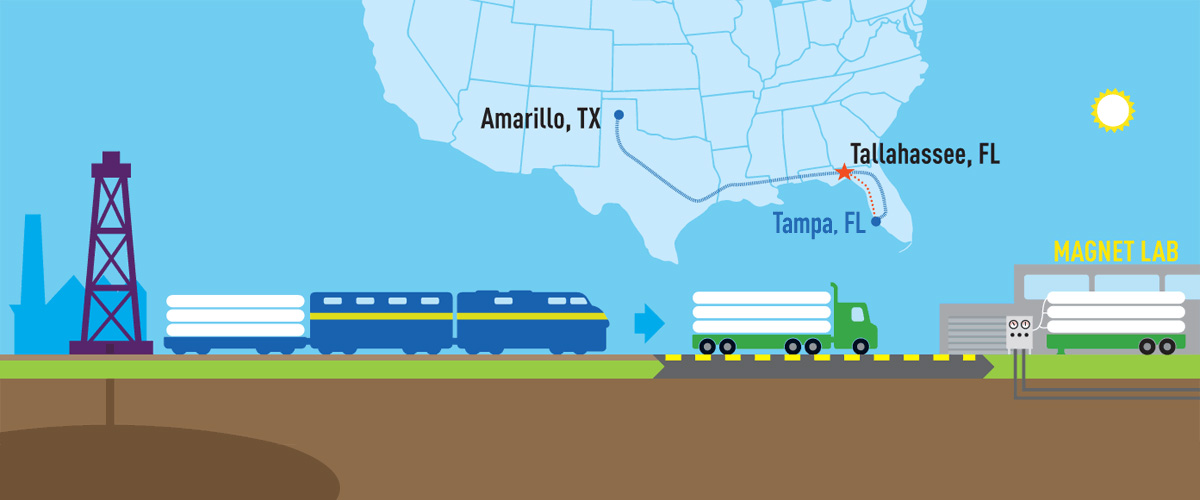

Helium is used to cool each of the lab’s many superconducting magnet systems: the lab’s flagship, 45 tesla hybrid magnet, the three magnets in the lab’s Millikelvin Facility and the 900 MHz magnet, which is the world’s strongest MRI scanner. Because we use so much of the stuff and are located near a major distribution center, the lab is relatively lucky; the MagLab pays between $4.00 and $5.50 for a liter. Compare that to $10-$12 a liter in New England and up to $25 a liter in China, and you see why conserving, recycling, and monitoring the remaining supply of helium is international news.

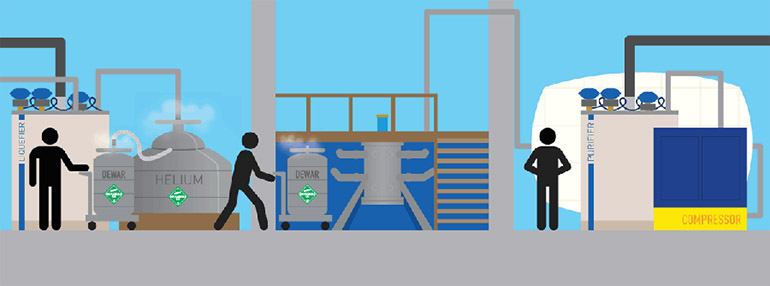

Helium is supercooled and liquefied for use in magnets. It is then conserved in a holding tank for its next use.

It was this need to both conserve helium and cut costs that prompted the lab to launch its helium-recovery project. Today — six years and $7 million later — the projected savings are staggering. Pre-upgrade, the lab typically spent upwards of $1 million per year on helium deliveries. That number is expected to drop to a projected $250,000 annually. Because recycling a liter of helium costs a relatively modest $1.50, that dramatic drop in expenditure should recoup the cost of the system in three to four years.

An essential research resource

Labs like the MagLab use liquid helium because it gets colder than anything else so freely available, and it remains liquid even at the lowest temperatures. At minus 452.1 degrees Fahrenheit, it’s got the lowest known boiling point of any element on the periodic table. Superconductivity — a phenomenon both studied at the MagLab and used in our magnet systems — is only presently possible in ultra-cold environments, and our suite of superconducting magnets couldn’t function without it. Helium is the only commercially available, easily transportable substance that gets so cold. Of course, the lab has plenty of resistive magnets that don’t require the use of helium, but these often can’t facilitate the same kind of low-noise environment needed for subtler scientific observations, and they’re useless for the type of imaging you can do in an MRI machine.

Improving diagnostics & infrastructure

Imagine if instead of a check engine light or a temperature gauge, your car had only a blinking light that said, “SOMETHING IS WRONG.” Pretty annoying, right? That’s roughly what the lab’s cryogenics support staff were working with before the upgraded system was installed. A broken recovery system could also result in some tough choices — stop a scientist’s experiment or continue it and waste helium?

MagLab staff lay pipes for the helium-recovery project.

Hannahs says of the transition, “With the old recovery system, we had very little instrumentation to try to figure out what was actually going on. Keeping helium clean is a huge job. When helium gets polluted with water or air, it’s a nightmare and you have people working until 3 a.m. to make sure it doesn’t cost users magnet time. Air in the helium is bad, and water is REALLY bad. With the new system, it’s really improved diagnostics and given our team members the tools to do their job a lot better with a lot less stress and a lot more reliability. It takes away that feeling of crisis mode that our cyrogenics team has taken as part of its job for 15 years.”

Equipment can only take the lab so far; retooling the lab’s helium efficiency requires an infrastructure overhaul from the (under)ground up. On many weekends, crews roam the lab’s halls trying to isolate sources of helium leaks and contamination. These leaks harm efficiency, of course, but they also bring air and water into the purifier, costing more time and money than necessary. Some sections of pipe are so deeply buried inside the building that the facilities team is still figuring out how to access them.

Modernizing magnet systems

Helium loaded into a magnet stays cool for a highly variable amount of time, depending on the researcher’s goals and the magnet’s construction. Keeping a steady, stable experimental-environment is a heck of a lot more helium-efficient than an experiment where a sample must be rapidly cooled.

The lab’s 900 MHz superconducting magnet, otherwise known as the world’s strongest MRI machine, uses a full quarter of the lab’s helium on its own — as much as 1,500 liters a week. Built seven years ago, the 900 MHz was the first magnet of its kind. Were this magnet designed again from scratch, its consumption would be lower. Another quarter of helium is used by the lab’s Millikelvin Facility — where not only does the helium cool the magnet, it also cools the sample to a fraction of a degree above absolute zero.

This might sound outrageous, but everything’s relative, and superconducting magnet systems operate far more cheaply than the lab’s electromagnets. Fifteen hundred liters of helium in a week at $4 dollars a liter is $6,000, right? Compare that to the thousands of dollars per hour a resistive magnet can use in electricity costs, and it’s easy to understand why engineers are moving toward superconducting systems. At the MagLab and elsewhere, newer magnets and MRI systems are designed with helium efficiency as an important consideration. One new magnet will have a self-contained recycling system with a built-in fridge, and should use only 300 liters of helium per year.

“We’re going to get more large superconducting systems and hybrid magnets; it’s how the lab will grow,” said Hannahs. “It comes down to smart design meeting smart resource management."

This story was originally published in Issue 9 of flux magazine, a discontinued publication of the National High Magnetic Field Laboratory.

Related Resources - will move to sidebar with content picker

- Cryogenics for English Majors: Fear not, right-brained friends: Science and art intersect in plenty of places, and this is one of them. Samuel Taylor Coleridge lends a hand as we explore cryogenics — how to get things fantastically frigid — and the fascinating element that makes it all possible.

- The 900 MHz Magnet: The Strongest MRI Machine in the World: An audio slideshow on this unique and powerful superconducting magnet.