You know those kids who just never seem satisfied with your answer? When grownups respond to their questions with evasive or ill-informed replies, they're like little pit bulls and won’t let go. "But why?" they insist, again and again. "How come?"

Charlie Sanabria wasn't one of those kids. Born in Colombia, he did not, as a boy, want to rock the boat.

"As a kid I just wanted to do things right. I wanted to get good grades. I wanted to be part of the soccer team. I was very industrious and just driven by recognition," said Sanabria, now 29, whose voice bears a trace of his native Spanish.

He saw life as a sequence of boxes that needed to be checked. "Like, get this step done, get it over with, do it right, and move on to the next, then on to the next and the next," he said.

Those steps included landing a spot in a good college and snagging a decent job in science. And he ended up with both, starting a degree in mechanical engineering at Florida State University and a part-time job nearby at the National MagLab's Applied Superconductivity Center (ASC).

Somewhere along the way, the curiosity switch flipped on in his brain. He began reading more — not for class or the lab, where he studied niobium-tin superconductors, but just because he wanted to know. He read about a wide range of topics: the history of science, the cosmos, evolutionary biology, the enlightenment and the American Revolution. His appetite for knowledge grew. He asked more and more questions.

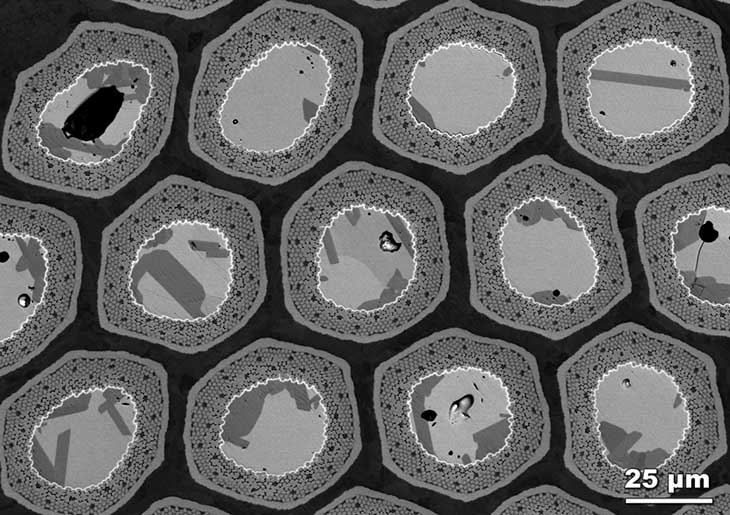

A group of filaments that were heated to 400 degrees Celsius for eight hours. Rings of Nausite (the squiggly, white circles), which can impair performance, have formed around the filaments’ copper-tin core, suggesting problems with this heat treatment method.

Sanabria went on to pursue a PhD, continuing his work at the ASC. For his thesis, he took on a problem facing CERN, the European laboratory that is home to the Large Hadron Collider. The LHC is a 27-km-long, underground "racetrack" that uses strong superconducting magnets to smash atomic particles together, enabling discoveries about nature's tiniest building blocks, like the Higgs boson. CERN is already planning for the LHC’s successor — the Future Circular Collider (FCC) — featuring a track four times longer with more than five thousand magnets, each twice as strong as those currently in place. The job of the magnets is to keep the particles traveling along the tunnel's circular path; without them, the particles would careen into the curves like out-of-control racecars.

One key to making those magnets stronger is increasing the performance of the superconducting wires inside them. Made from niobium-tin filaments in a copper matrix, the wires conduct the high currents that produce the magnet's powerful fields. Sanabria worked with the company that makes those filaments, Bruker-OST (formerly Oxford Superconducting Technology), to see where there was room for improvement.

His specific challenge was to find a way to increase the conductor's current density, which would help boost the magnets' strength from 8 to 16 teslas. That would mean reducing the diameter of the filaments by more than half — from 55 to 25 micrometers — while maintaining the same current density of 1,500 amps per square millimeter.

In hot pursuit of an answer

Turning raw niobium-tin into superconducting wire is a lengthy process. First the metals are drawn into thin filaments, hundreds of which are bundled together and jacketed into a matrix of copper to form a single wire. Those wires are twisted into cables, which are then "cooked" at very high heat, following a specific recipe. This activates the wires' superconducting properties so that, when they are cooled to a low enough temperature in the finished magnet, they will perform their superconducting magic, conducting current without any energy loss.

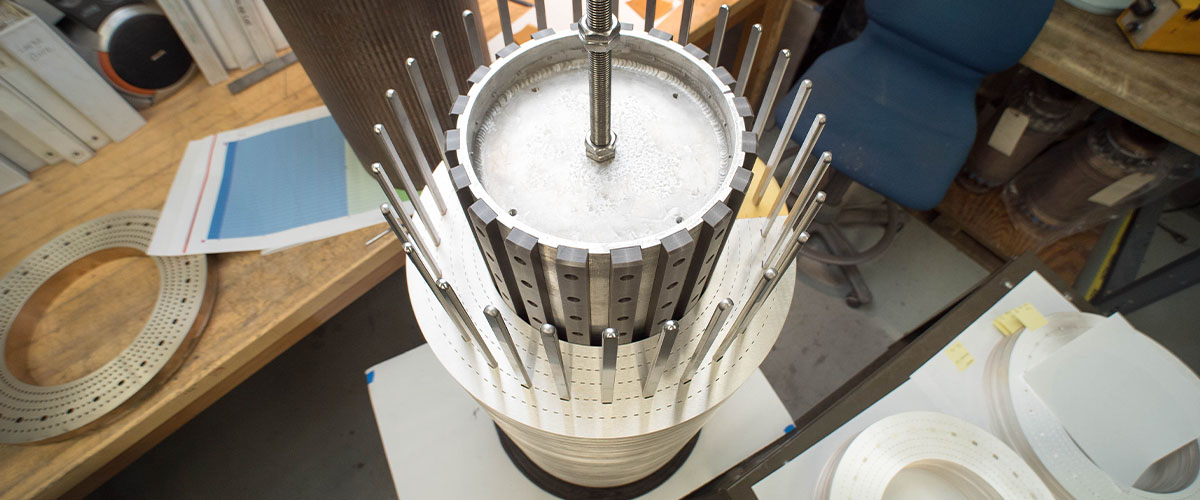

Charlie Sanabria near the furnace used for his research.

Sanabria began to suspect that heat-treatment process could be improved. For one thing, his research revealed that others shared his hunch. And Sanabria saw another red flag when he talked to engineers and technicians about the technique, which had been used to manufacture superconducting magnets for research laboratories for years.

"I started asking people, 'Why is this the same? Why hasn't it changed? What happens at this or that temperature?'" Sanabria recalled. "It is a very simple question. Nobody could tell me the answer."

The process, it appeared, had come about through trial and error. People tested different combinations of temperatures and cooking times until they hit upon something that worked, Sanabria said. Then they stuck with it.

Sanabria figured “good enough” could be improved upon considerably. Inspired by Michael Faraday, Ernest Rutherford and other science heroes he had been reading about, he kept asking questions and challenging the status quo.

"Neither the wire engineers nor the magnet manufacturers had taken the time to really look at what was going on inside the wires," he said. "And that's exactly what I did."

Using metallography and microscopy, Sanabria took a very close look at the wires at different stages of heat treatment. He discovered that the problem lay in a compound that forms in the material during heat treatment, known as Nausite. As it turns out, Nausite (discovered at the ASC in 2002 and named after the student who identified it, Michael Naus) plays a helpful role in the heat treatment process. However, too much of that good thing can, Sanabria found, be detrimental.

With his partners at Bruker-OST, Sanabria ran a sequence of experiments that helped them refine the existing three-stage heat treatment. Each stage lasted two days, each at a higher temperature, with the final phase reaching 650 degrees Celsius. Sanabria figured out that a two-step process, using somewhat cooler temperatures but much longer cooking times, worked better.

How much better? The revised treatment produced significantly thinner (35 microns in diameter) filaments boasting a current density of 1,400 amps per square millimeter, just 100 amps shy of the target 1,500.

"He's extremely close," said ASC Director David Larbalestier, "and the extraordinary thing is, he's doing it with one of today's products — just showing Bruker-OST how to make the niobium-tin in a more efficient and effective way."

Taking the broad view

Sanabria uses a scanning electron microscope to view the structure of materials at the atomic level. He has been using the technique for some eight years, long enough to have gotten pretty good at it — but also long enough to know that too much time spent staring at very tiny things can make a person lose perspective.

That's why, throughout his PhD work, Sanabria made it a point to come up for air for an hour or two each day to read about the wider context of his research: the history of magnet manufacturing, quarks and hadrons, the beginning of the universe.

"It was so important to me to keep the big picture there, to understand everything from the beginning to the end," he said. "And I think that was the main reason I was successful: Because I took my time to really dig and really understand."

Larbalestier could think of a few other reasons Sanabria succeeded.

"The great thing about Charlie is he is very creative and very energetic," Larbalestier said. "He has a very positive personality. He knows how to get people to work together and he creates a kind of excitement."

Sanabria has completed his PhD thesis and will soon move on to his next challenge. When he looks back on the years-long process, he draws a couple of lessons. First, be curious. Second, defy conventional thinking. And perhaps most importantly, be true to the scientific method.

"As humans, we have developed a method that takes into account that we humans are fallible and we tend to make mistakes," Sanabria said. "That system, the scientific method, is a foolproof system that rejects things that don't work and takes things that do work."

"That's how science works," he continued. "You ask a question, and if you don't find an answer that satisfies you … you've got to keep looking."

View more images from Sanabria's research.

By Kristen Coyne

Image credits: Filament image by Charlie Sanabria. Charlie Sanabria photos by Stephen Bilenky.