What did scientists discover?

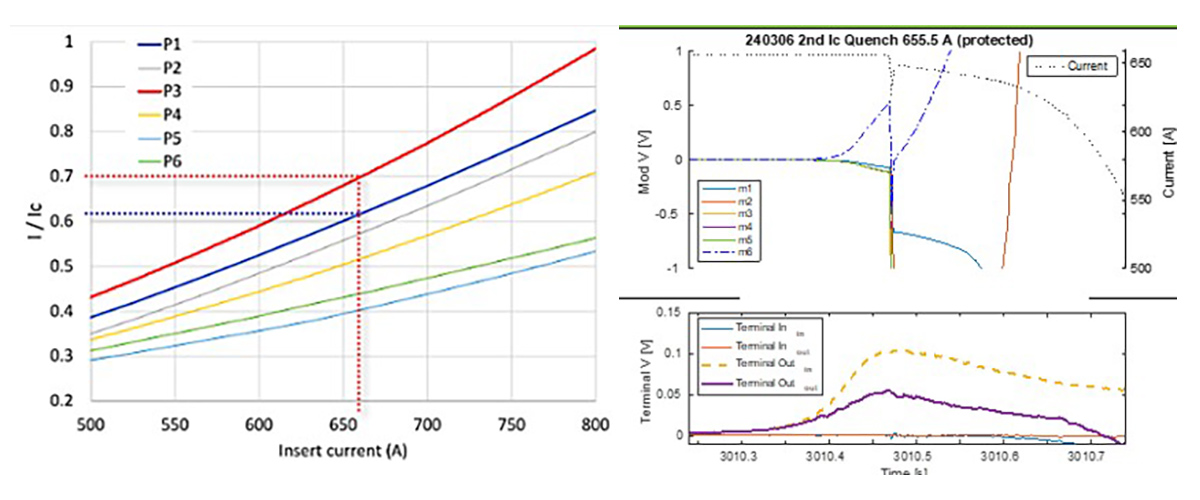

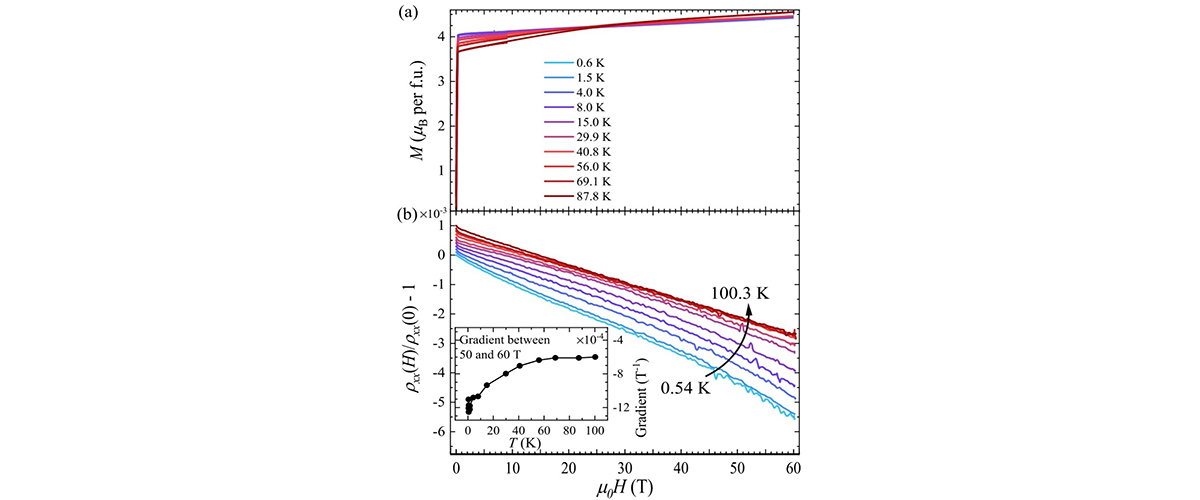

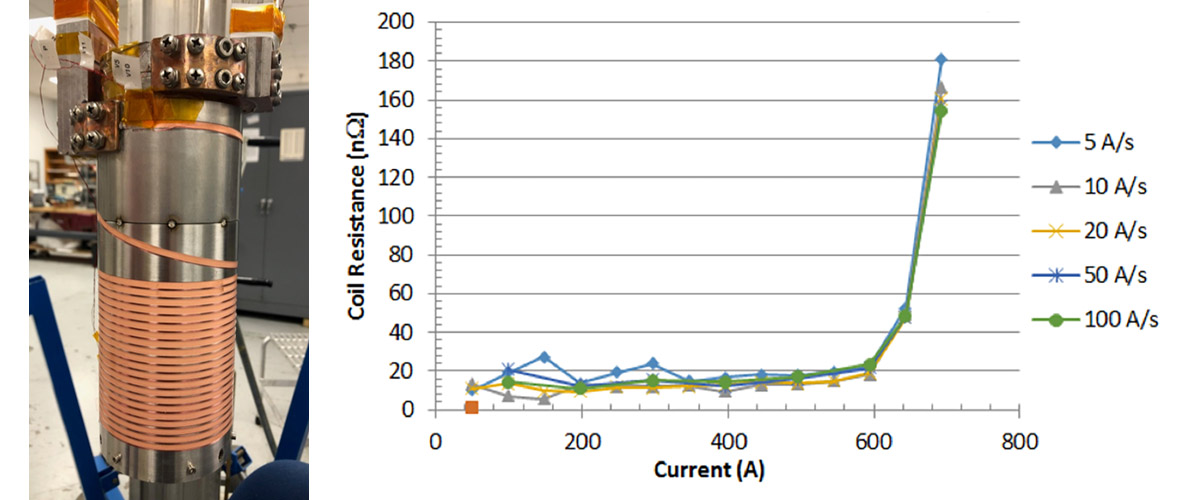

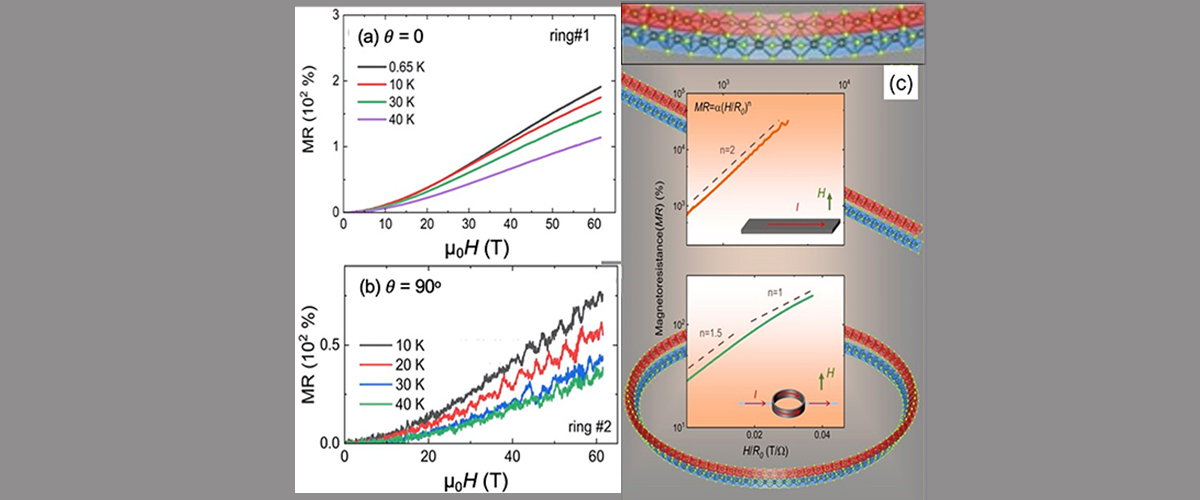

A coil made from over 1 km of ReBCO tape was successfully operated at its predicted critical current (Ic), as determined by detailed tape performance measurements. ReBCO is a high-temperature superconductor (HTS) made in tape form, just a few millimeters wide and about 0.1 mm thick, with only 1 micron of superconducting material. The name ReBCO comes from its chemical composition: Rare earth – Barium – Copper Oxide. These tapes can be used to create coils that generate ultra-high magnetic fields.

Why is this important?

This demonstration confirms the methods used to design a REBCO-wound magnet system. By starting with precise tape characterizations for each piece of tape, these material properties are input into advanced numerical models that predict the coil's behavior. The simulations calculate how magnetic field vectors affect tape performance, considering both the field's strength and direction. They also account for the stresses and strains caused by the coil's electrodynamics. The latest test coil's experimental results closely match the predictions, boosting confidence in developing a 40T All-Superconducting Magnet.

Who did the research?

Abraimov, D., Arroyo, E., Bai, H., Belton, M., Bird, M., Bosque, E., Cantrell, Dixon, I., Gavrilin, A., Jarvis, B., Kim, K., Lu, J., Marshall, W., Suetomi, Y.

National High Magnetic Field Laboratory (National MagLab)

Why did they need the MagLab?

Only a few places in the world have magnet test facilities large enough and with strong enough magnetic fields to test and develop large coils. The experiments were conducted in the 11.4T outsert of the World Record 45T Hybrid magnet, after removing its resistive insert. Additionally, the NHMFL provides access to liquid helium and has an efficient helium recovery system, which is essential for advancing this magnet technology.

Details for scientists

- View or download the expert-level Science Highlight, Demonstrations of Operating Large REBCO Coils to High Fractions (>70 %) of Their Critical Current

Funding

This research was funded by the following grants: K. M. Amm (NSF DMR-2128556); M. D. Bird (NSF DMR-2131790)

For more information, contact Tom Painter.