What did scientists discover?

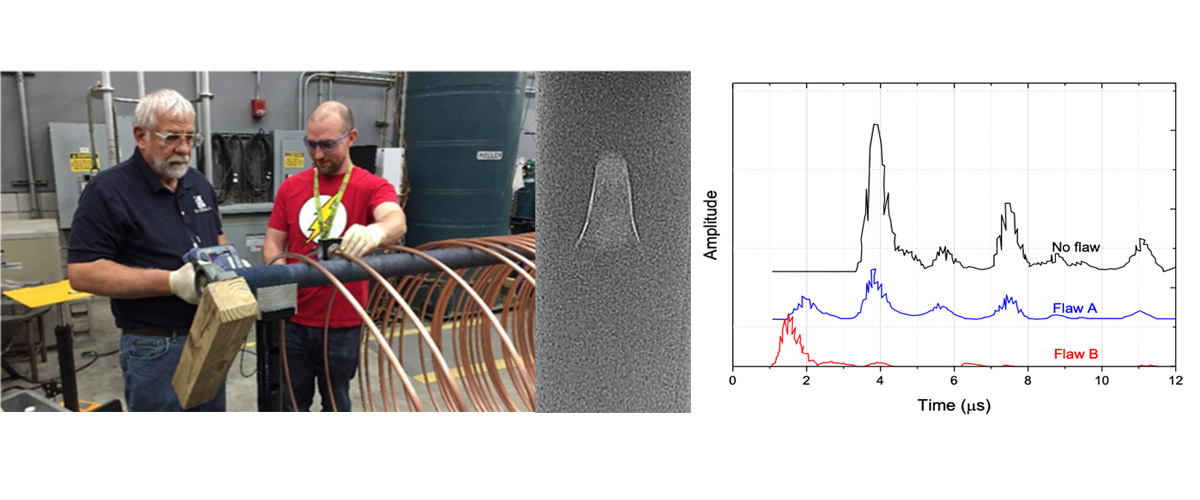

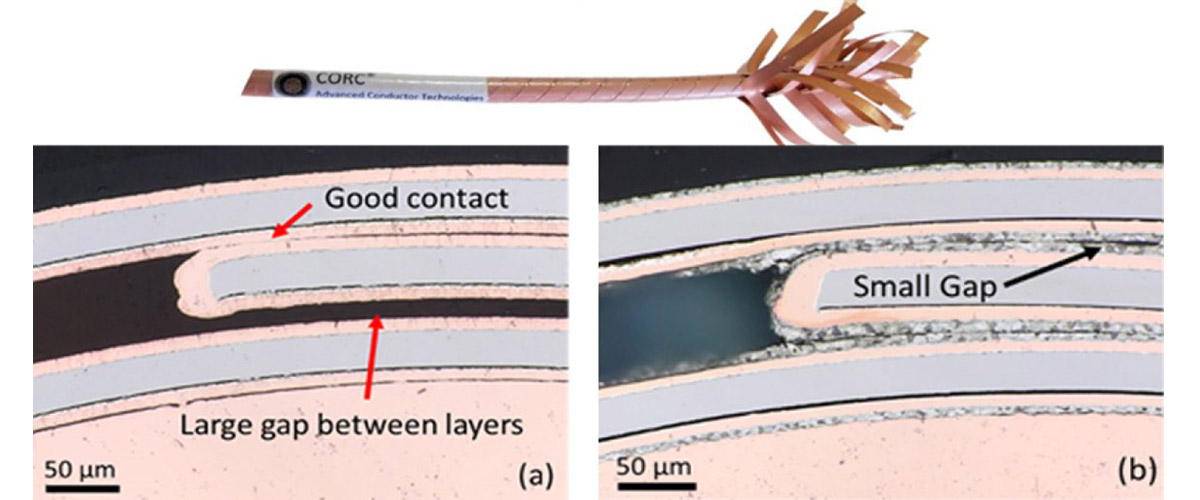

The MagLab has developed and tested new methods for detecting flaws in wire being received from commercial suppliers. X-ray radiography, eddy current testing and ultrasonic testing were evaluated. The system based on eddy-currents was most effective and has been implemented to inspect the long lengths of wire necessary for the construction of pulsed magnets. In addition, the MagLab developed methods to repair surface defects and to minimize the chance of creating internal cracks.

Why is this important?

When drawing high-strength wire, internal chevron-shaped cracks can occur due to a number of causes, among them an unsuitable drawing-die schedule, too-rapid drawing speed, or inadequate lubrication. In addition, very small dents and inclusions of foreign materials on the wire surface can occur. Because the MagLab’s pulsed magnets operate at 90% of ultimate stress, small flaws in the conductors can significantly reduce the lifetime of the magnets. Although all pulsed magnets eventually fail due to high mechanical stresses, as a result of this work, the MagLab expects the lifetime of future pulsed magnets to exceed those of past pulsed magnets.

Who did the research?

Jun Lu, Todd Adkins, Iain Dixon, Doan Nguyen and Ke Han

National MagLab

Why did the MagLab need to do this research?

The MagLab has a unique need to develop its own expertise in the detection and mitigation of conductor defects in order to improve the performance of its own pulsed magnets. World-record performance often demands the development of unusual expertise!

Details for scientists

- View or download the expert-level Science Highlight, Nondestructive testing and minimizing defects in high-strength conductors for use in pulsed magnets

- Read the full-length publication, Nondestructive Testing of High Strength Conductors for High Field Pulsed Magnets, in IEEE Transactions on Applied Superconductivity

Funding

This research was funded by the following grants: G.S. Boebinger (NSF DMR-1157490 and 1644779)

For more information, contact Jun Lu.