What did scientists discover?

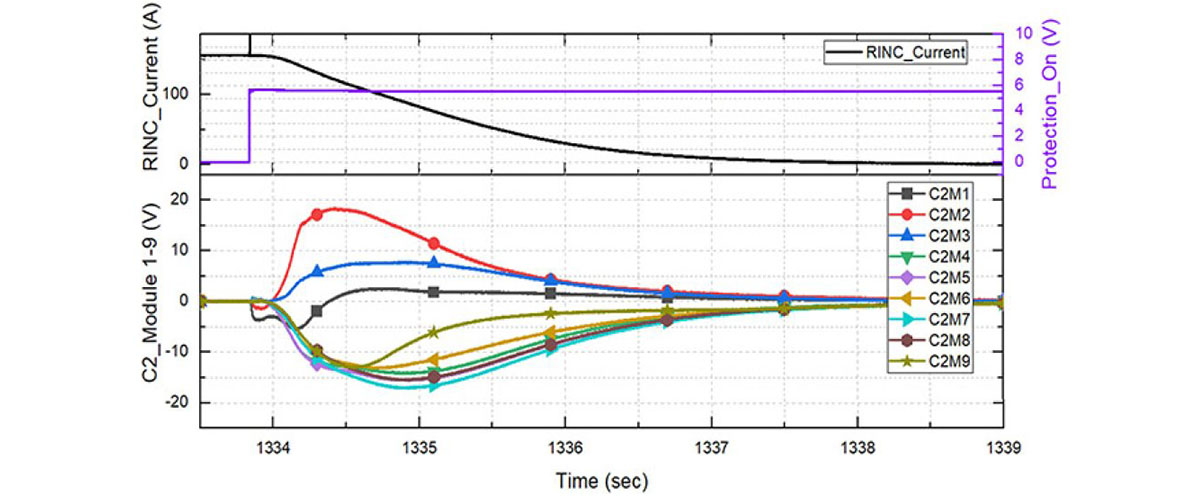

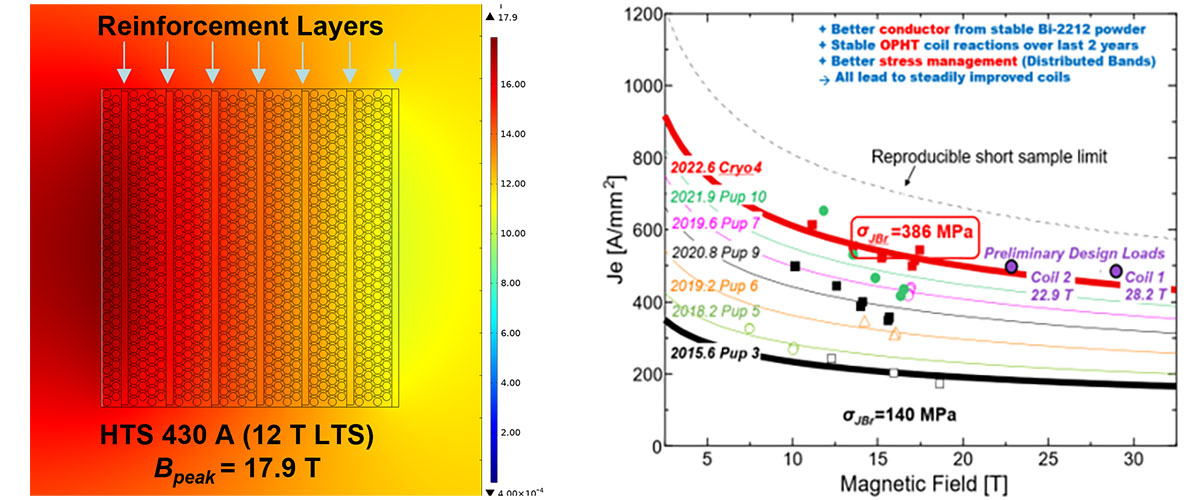

A novel quench protection system for large high-temperature superconducting (HTS) magnets was demonstrated. A large test coil was fabricated using REBCO high temperature superconductor that does not have electrical insulation between the turns of superconductor. The successful tests of this coil demonstrated the effectiveness of a process to precisely control the electrical resistance between superconducting turns. It also demonstrated a strategy to safely protect the magnet through controlled, symmetric quench propagation that is nucleated simultaneously from the top and bottom of the coil.

Why is this important?

TThe MagLab has embarked on an ambitious NSF-funded project to design a 40T all-superconducting HTS magnet. The “resistive insulation” strategy described above is one of the novel magnet technologies being considered in place of traditional insulations for several reasons: (1) it results in magnets that are stable despite conductor defects, and (2) it has the potential to result in more compact and lower cost magnets.

Who did the research?

Iain Dixon, Kwangmin Kim, Jun Lu, Denis Markiewicz, Emsley Marks, Peng Xu, Hongyu Bai

National High Magnetic Field Laboratory

Why did the MagLab need to do this research?

The MagLab is host to a number of key elements required for success: (1) a large-bore superconducting magnet; (2) a pulse-forming network used to energize the protection system; (3) the software used to compute the strain distribution in the magnet, including the effects of screening currents; and (4) the team of experts capable of designing, building, and conducting such a demanding test.

Details for scientists

- View or download the expert-level Science Highlight, 19T Resistive Insulation Test Magnet for Demonstration of Technology Applicable to a 40T All-Superconducting Magnet

Funding

This research was funded by the following grants: G.S. Boebinger (NSF DMR-1644779); M. D. Bird (NSF DMR-2131790)

For more information, contact Mark Bird.