What is the finding?

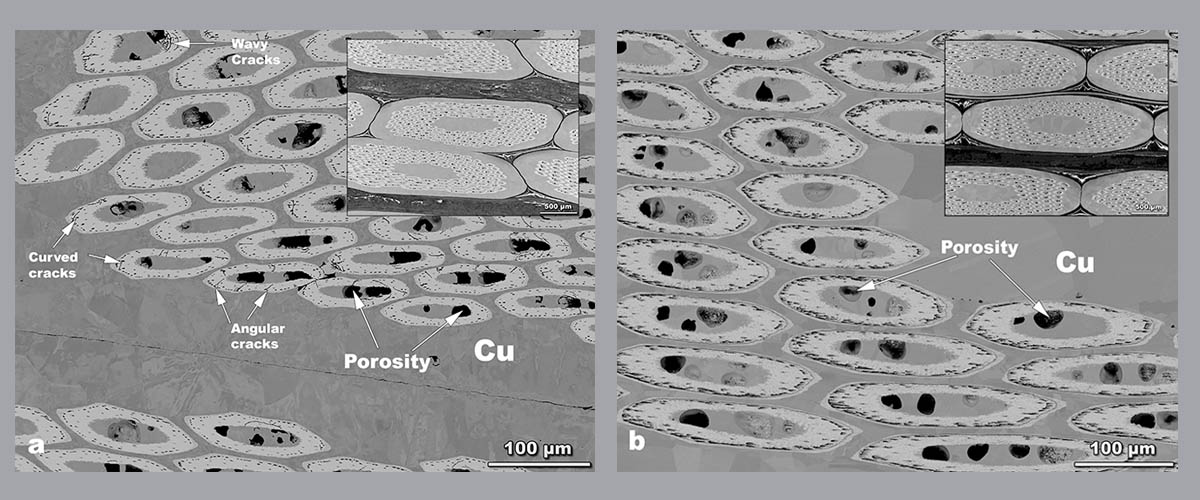

Cracks were discovered in a prototype Nb3Sn superconducting accelerator magnet coil designed for the High Luminosity Upgrade of CERN's Large Hadron Collider. The nature of conductor damage was characterized. By comparing with control samples, researchers determined that high stresses during assembly led to the formation of the cracks.

In addition, copper hardness within the Nb3Sn conductor was discovered to be a tell-tale indicator of magnet damage due to excessive stress.

Why is this important?

The results here will help guide future designs of Nb3Sn magnets for CERN's high-luminosity upgrade, work that will advance the frontier of particle physics. Other large superconducting magnets, including the MagLab's 45T Hybrid and 32T SC magnets, medical magnets, and magnets for particle accelerators also produce extreme stress during operation. While magnets are designed to support high stress, margins are now so close to physical limits that stresses during assembly can lead to unacceptable degradation of magnet conductor. These new methods will allow actual stress levels in complex magnet structures to be compared to computer models.

Who did the research?

S Balachandran1, J. Cooper1, O. B. Van Oss2, P J. Lee1, L. Bottura3, A. Devred3, F. Savary3, C. Scheuerlein3, F. Wolf3

1Applied Superconductivity Center, National MagLab; 2Columbia University; 3CERN

Why did this research need the MagLab?

The MagLab's Applied Superconductivity Center is expert in microstructural evaluation of Nb3Sn superconductors, including those used by CERN to fabricate these high-field accelerator magnets.

Details for scientists

- View or download the expert-level Science Highlight, Tracking the Potential for Damage in Nb3Sn Superconducting Coils from the Hardness of Surrounding Copper

- Read the full-length publication, Metallographic analysis of 11 T dipole coils for High Luminosity-Large Hadron Collider (HL-LHC), in Superconductor Science and Technology.

Funding

This research was funded by the following grants: CERN PO CA7854000, G.S. Boebinger (NSF DMR-1644779, State of Florida)

For more information, contact Lance Cooley.