What is the finding?

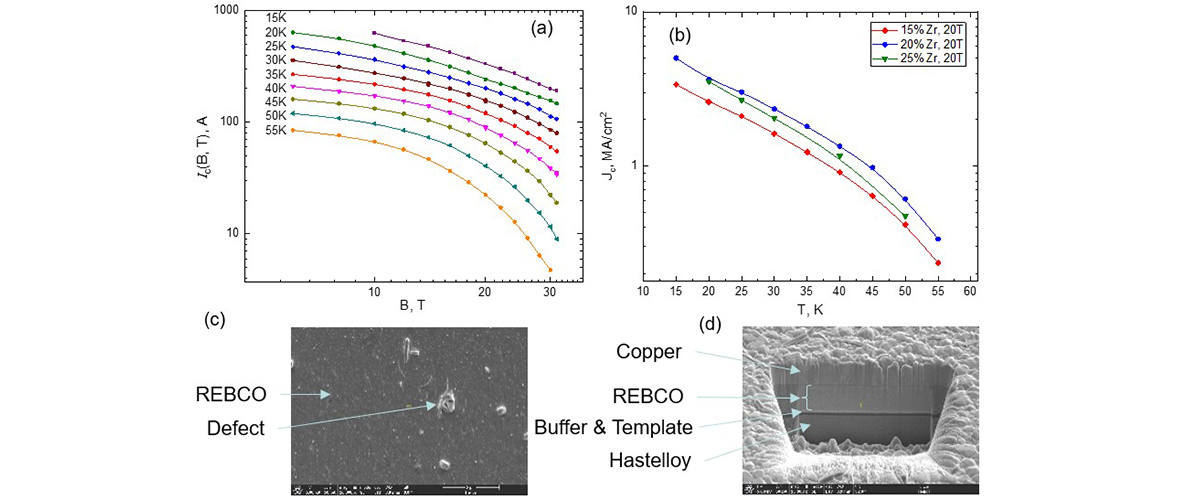

Superconductors can carry electric currents without any heat loss, up to a limit called the critical current (Ic). To improve Ic performance, manufacturers add oxide nanoparticles to ceramic REBCO superconductors. However, if not carefully balanced, these additions can negatively affect the REBCO ceramic's properties, especially for specific magnetic fields (B) and temperatures (T).

In collaboration with SuperPower Inc., a REBCO conductor manufacturer, we developed methods to measure their superconducting wires’ Ic values at a 20T magnetic field and 20K temperature, conditions that are required for fusion energy applications. We redesigned a variable-temperature probe to measure Ic(B,T) in the MagLab’s small-bore 31T magnets. We also used a Scanning Electron Microscope to check for defects and measure the thickness of the superconductor, with precise cuts made by an ion beam.

Why is this important?

Measuring the transport Ic(B,T) dependencies of full-width REBCO tapes gives direct feedback on properties for specific growth conditions. SuperPower then used this data to quickly improve their conductors. We also provided extensive data to magnet designers to enhance their technology, potentially leading to abundant energy sources. Using this difficult transport measurement technique eliminated uncertainties in the interpretation of the results.

Who did the research?

D. Abraimov1, J. Gillman1, Carina Zha1, Jan Jaroszynski1, L. Cooley1, Y. Zhang2

1National MagLab, Tallahassee, FL; 2SuperPower Inc., Glenville, NY

Why did they need the MagLab?

The MagLab has world-leading powerful magnets for testing conditions that conductor manufacturers can't achieve. Here, we used a resistive magnet to reach up to 31T. With our extensive experience in studying REBCO conductors, we are able to develop new techniques to support exciting new applications.. Our ongoing work to build world-record magnets helped develop these test methods, and improved conductors from SuperPower will support the next generation of world-leading magnets.

Details for scientists

- View or download the expert-level Science Highlight, Characterization of Improved SuperPower REBCO Tapes up to 31 Tesla Field

- Read the full-length publication, Development of general expressions for the temperature and magnetic field dependence of the critical current density in coated conductors with variable properties, in Superconductor Science and Technology

Funding

This research was funded by the following grants: K.M. Amm (NSF DMR-2128556); D. Abraimov (DE-SC0023177, DMR-2131790);

For more information, contact Lance Cooley.