What is the finding?

Nb3Sn coated superconducting radiofrequency (SRF) cavities could potentially operate in the 4–8K temperature range reached by compact refrigerators, enabling small and even portable x-ray, and intense electron beam sources. Present Nb3Sn cavity coating requires high temperatures, ~1200°C, eliminating the potential benefits of combining with a Cu cavity body.

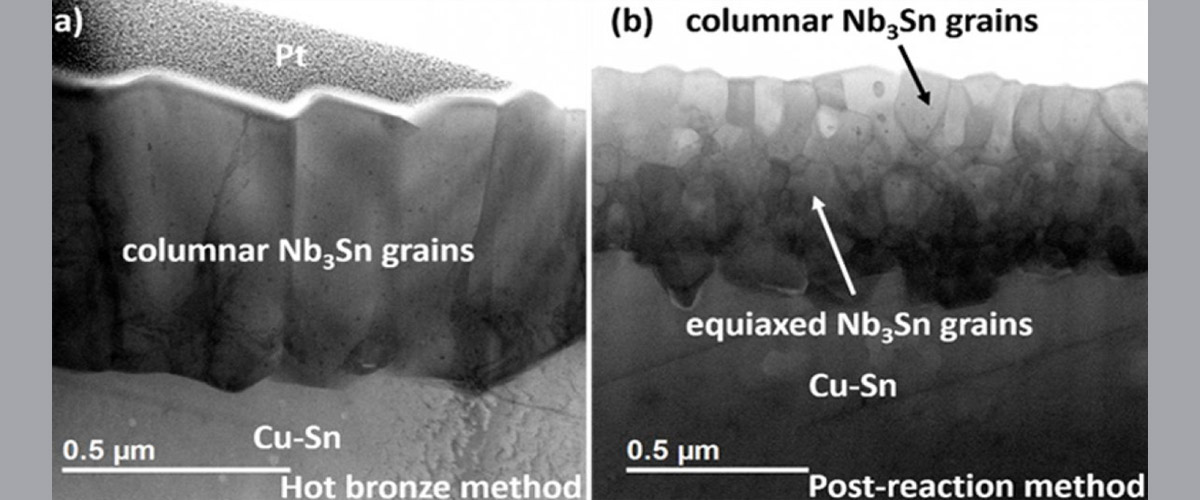

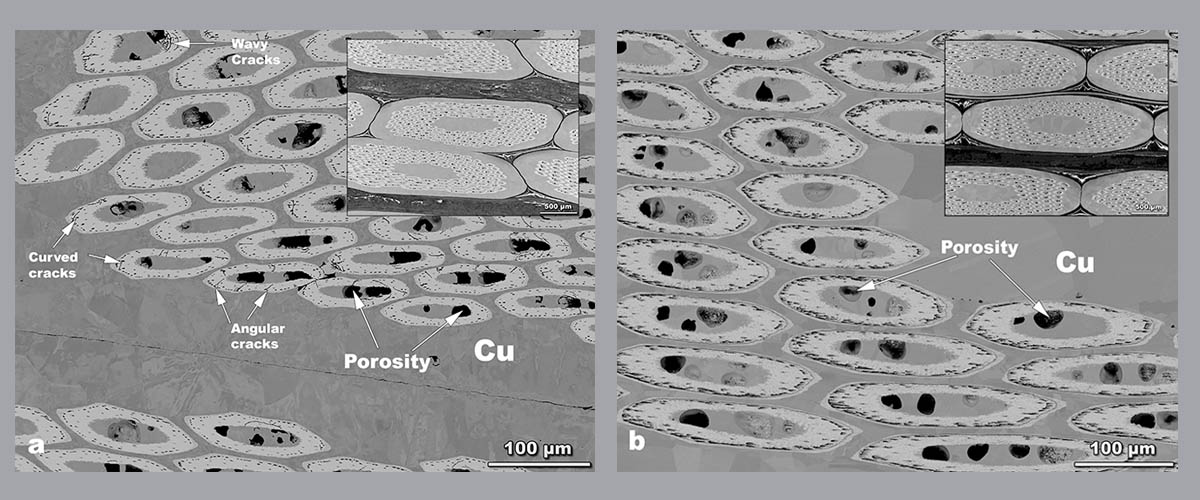

Researchers at ASC-National MagLab developed a new ~700°C "hot bronze" Nb3Sn coating recipe, scalable to cavity production, that can produce high quality Nb3Sn films on bronze substrates.

Why is this important?

This new recipe can be scaled to produce Nb3Sn surfaces inside copper shells to produce next-generation superconducting radio frequency (SRF) cavities. Such cavities will be able to operate at higher temperatures than the current state-of-the-art bulk niobium cavities, reducing capital and operational costs significantly, and paving the way to next generation of particle accelerators. Furthermore, the ability to operate at higher temperature – without the large and costly infrastructure required by superfluid helium – will enable future applications requiring compact, portable accelerators for industrial, medical, science, and environmental applications.

Who did the research?

Wenura Withanage1, Andre Juliao1,2, and Lance D. Cooley1,2

1Applied Superconductivity Center - National MagLab; 2Florida State University;

Why did this research need the MagLab?

The MagLab's Applied Superconductivity Center has long been a pioneer in advancing the synthesis and characterization of Nb3Sn superconducting wires. This expertise was used to address challenges faced by SRF cavities. The experiments required the use of new thin-film deposition equipment at the MagLab that is tailored for the study of Nb and Nb3Sn. The images in the Figure were taken using the state-of-the-art high-resolution electron microscopy facility at MagLab.

Details for scientists

- View or download the expert-level Science Highlight, Nb3Sn films via a novel hot-bronze method for compact accelerators

- Read the full-length publication, Rapid Nb3Sn film growth by sputtering Nb on hot bronze, in Superconductor Science and Technology

Funding

This research was funded by the following grants: L.D. Cooley (DOE DE-SC0018379), G.S. Boebinger (NSF DMR-1644779)

For more information, contact Lance Cooley.