What did scientists discover?

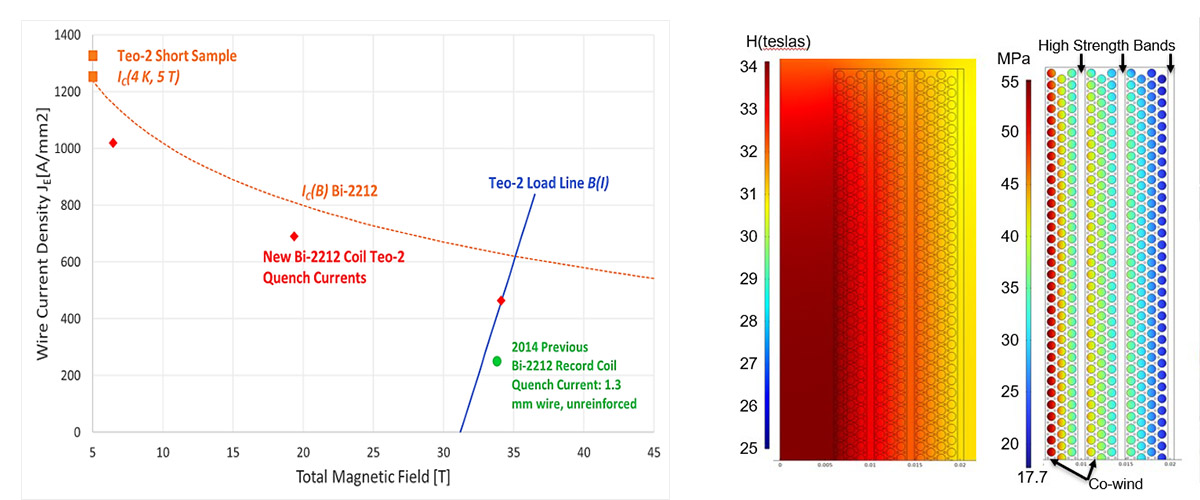

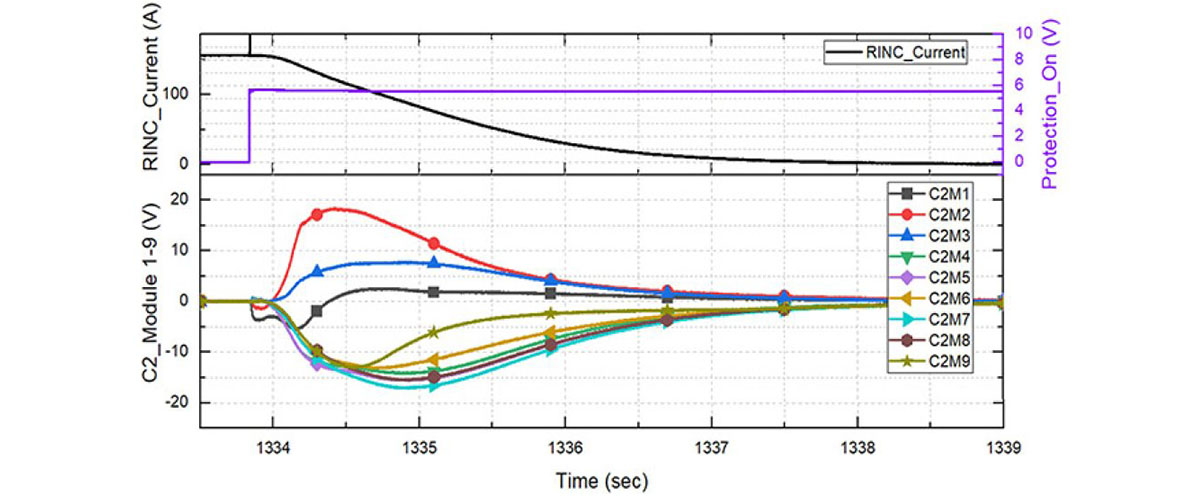

A set of Bi-2212 superconducting test coils produced a peak field of 34T at a wire current density (JE) of 464A/mm2, supporting a peak hoop stress up to 270MPa, well over the breaking stress of the bare wire. The coils were ramped at rates of up to 3200A/s with no performance degradation after high ramp rates.

Why is this important?

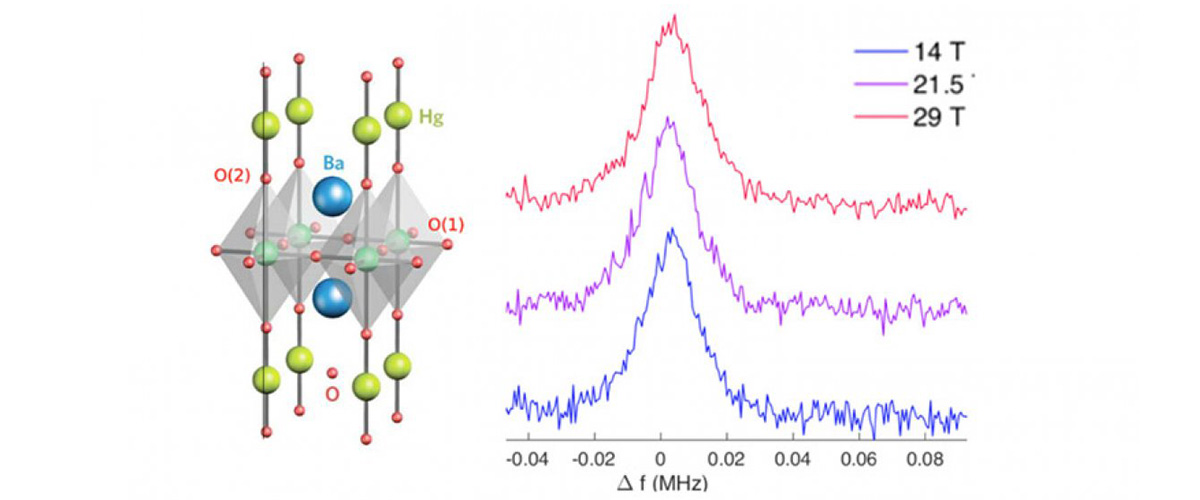

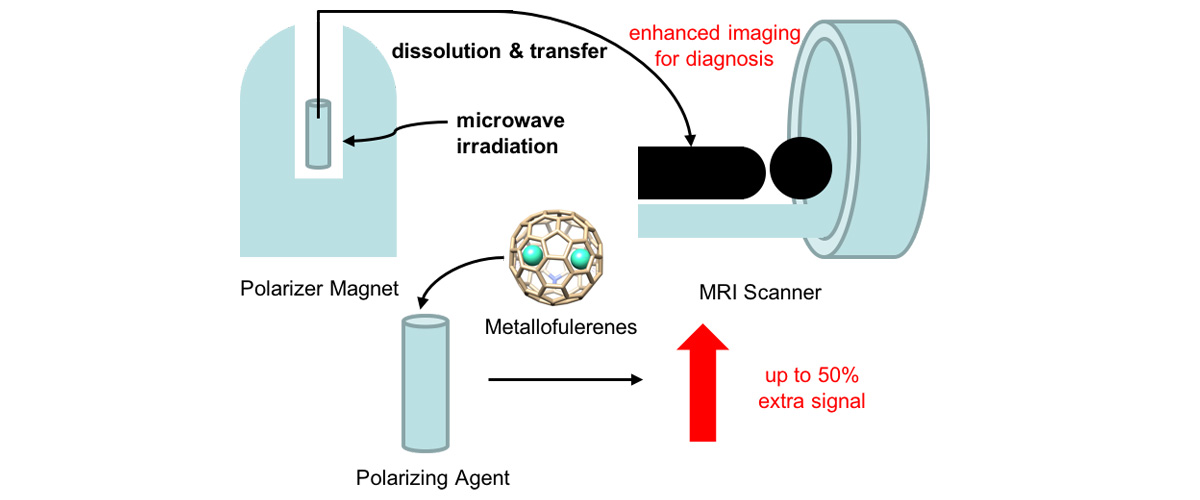

High magnetic fields are essential for many scientific and industrial applications, such as magnetic resonance imaging (MRI) in medicine, particle accelerators in physics research (e.g., Large Hadron Collider, nuclear fusion), and nuclear magnetic resonance (NMR) spectroscopy in chemistry.

Compact ultra-high-field (>25T) magnets will generate stresses of 200MPa to 500MPa, well beyond the strength of any unreinforced superconductor. Fast current ramp-rates will enable rapid sample testing in future 25T-class HTS research magnets and will be required for future higher field accelerator magnets and compact fusion ohmic heating magnets.

Who did the research?

Youngjae Kim1, Daniel Davis1, Ulf Trociewitz1, Shaon Barua1, Emma Martin1, Lance Cooley1, David Larbalestier1

1Applied Superconductivity Center, National MagLab, Florida State University

Why did they need the MagLab?

The MagLab’s Applied Superconductivity Center has made significant advances in magnet technology development of Bi-2212 round wire, including over-pressure heat treatment in our unique magnet-sized furnaces and internal coil reinforcement allowing magnets to reach the full potential of the high current densities available at fields well in excess of 30T. The MagLab’s 31T DC resistive magnet enables small test coils to be pushed to their limits under conditions replicating the intended application of commercial compact ultra-high field research magnets.

Details for scientists

- View or download the expert-level Science Highlight, Operation of High Temperature Superconducting Bi-2212 Test Coils up to 34T

- Read the full-length publication, System and Method to Manage High Stresses in Bi-2212 Wire Wound Compact Superconducting Magnets, in Appl.No. 16390512

Funding

This research was funded by the following grants: D.C. Larbalestier (US DOE-OHEP DE-SC0010421); G.S. Boebinger (NSF DMR-2128556); Florida State University Office of the Vice President for Research special allocation for Bi-2212 commercialization

For more information, contact Ulf Trociewitz.