What did scientists discover?

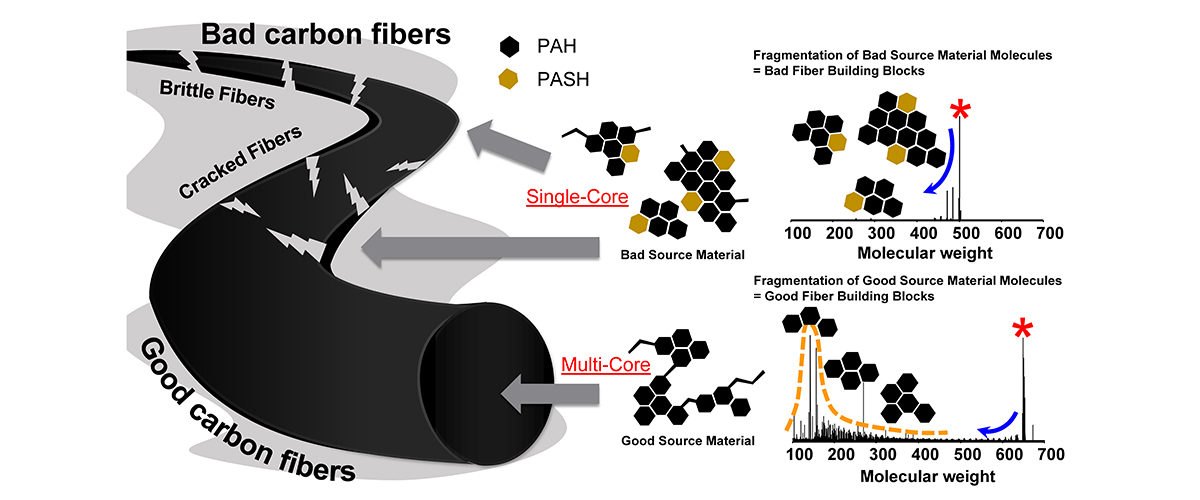

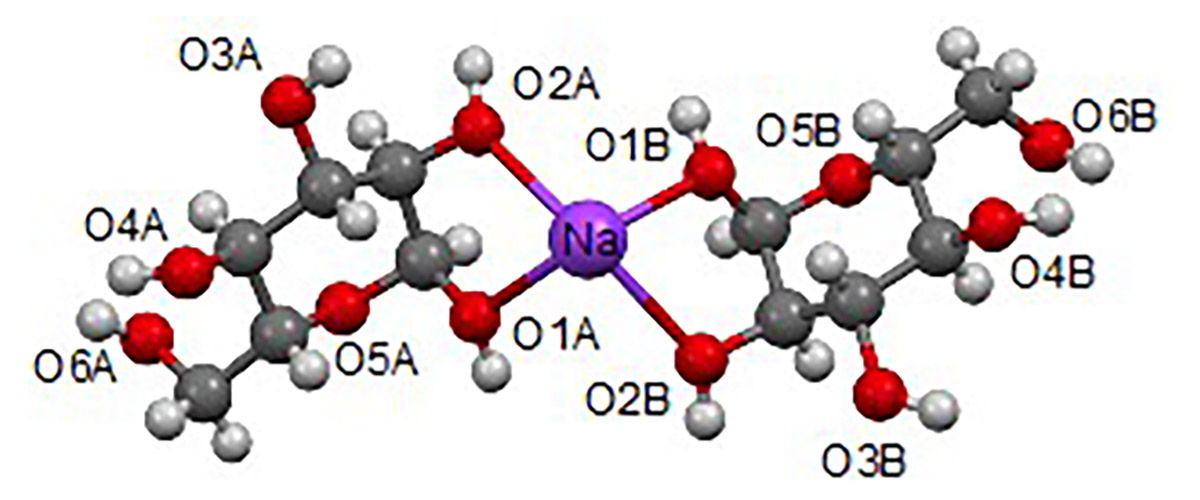

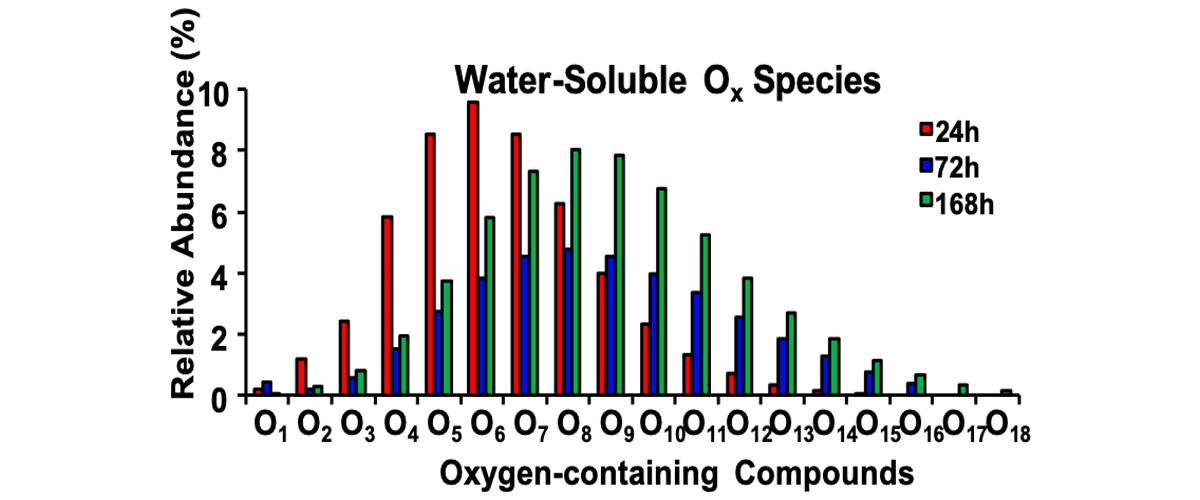

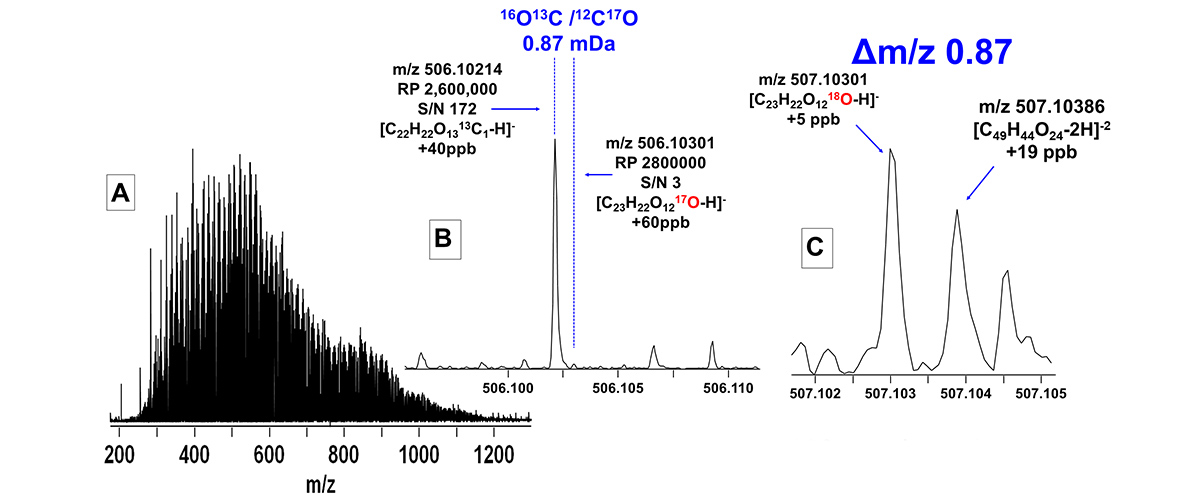

Low-cost petroleum feedstocks are rich in asphaltenes that can be used to make carbon fiber. Using ion cyclotron resonance mass spectrometry (21T FT-ICR MS), scientists measured the mass of asphaltene molecules. They found that good carbon fiber precursors have more low molecular weight building blocks and fewer sulfur-containing molecules, distinguishing them from poor precursors.

Why is this important?

Carbon fibers are crucial for applications like aerospace and medical devices, but they are usually made from expensive polyacrylonitrile. By understanding the complex makeup of asphaltenes, we can transform them into carbon fibers. This allows low-cost petroleum feedstocks to be processed into excellent carbon fiber precursors through thermal treatment. Using these materials could cut production costs by 90% and lower greenhouse gas emissions.

Who did the research?

Martha L. Chacón-Patiño,1 Anika Neumann,2 Christopher P. Rüger,2 Paolo G. Bomben,3 Lukas Friederici,2 Ralf Zimmermann,2 Erik Frank,4 Philipp Kreis,4 Michael R. Buchmeiser,4 and Murray R. Gray3

1National High Magnetic Field Laboratory; 2Joint Mass Spectrometry Centre, University of Rostock, Germany; 3Alberta Innovates, Canada; 4German Institutes of Textile- and Fiber Research, Denkendorf, Germany

Why did they need the MagLab?

The MagLab 21-tesla ICR mass spectrometer can uniquely identify the complex mix of molecules in asphaltenes, helping to pinpoint the features needed for high-quality carbon fibers. Using 21T FT-ICR MS with gas-phase fragmentation to study asphaltene samples can guide the improvement of petroleum feedstocks into good carbon fiber precursors.

Details for scientists

- View or download the expert-level Science Highlight, Chemistry and Properties of Carbon Fiber Feedstocks from Bitumen Asphaltenes

- Read the full-length publication, Chemistry and Properties of Carbon Fiber Feedstocks from Bitumen Asphaltenes, in Energy Fuels, Data Set.

Funding

This research was funded by the following grants: G.S. Boebinger (NSF DMR-1644779 & DMR-2128556); Zimmermann (EU_FT-ICR MS, 731077, and DFG INST 264/56)

For more information, contact Chris Hendrickson.