Contact: Jamel Ali

TALLAHASSEE, Fla. — Take a look at your fingernails. Now hold that look for a second. You probably didn't see a change, but in that heartbeat, your fingernails grew by a nanometer.

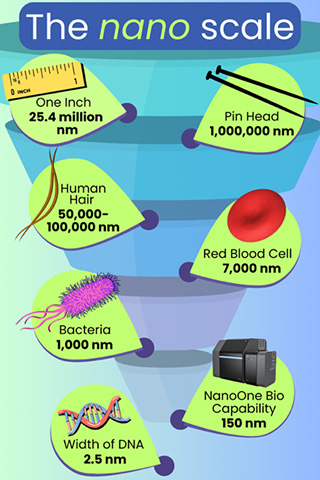

A nanometer — a billionth of a meter — is so small it's hard to fathom. The tiny head of a pin is a million nanometers wide. A single sheet of paper is 100,000 nanometers thick. And, yes, your fingernails grow a nanometer every second.

Now, scientists at the National High Magnetic Field Laboratory have acquired a new tool enabling research at that super-small scale. It is the first facility in the U.S. to receive an instrument like this.

The NanoOne Bio 3D printer is capable of printing in sizes as small as 150 nanometers. That's about 50 times smaller than a red blood cell and thinner than the walls of blood vessels in the tiniest capillaries. Researchers expect this new tool will allow better pharmaceutical testing and aide in the creation of nanorobots for healthcare applications.

"We're excited to have a system that can print at the smallest scale of any printer," said FAMU-FSU College of Engineering Assistant Professor Jamel Ali.

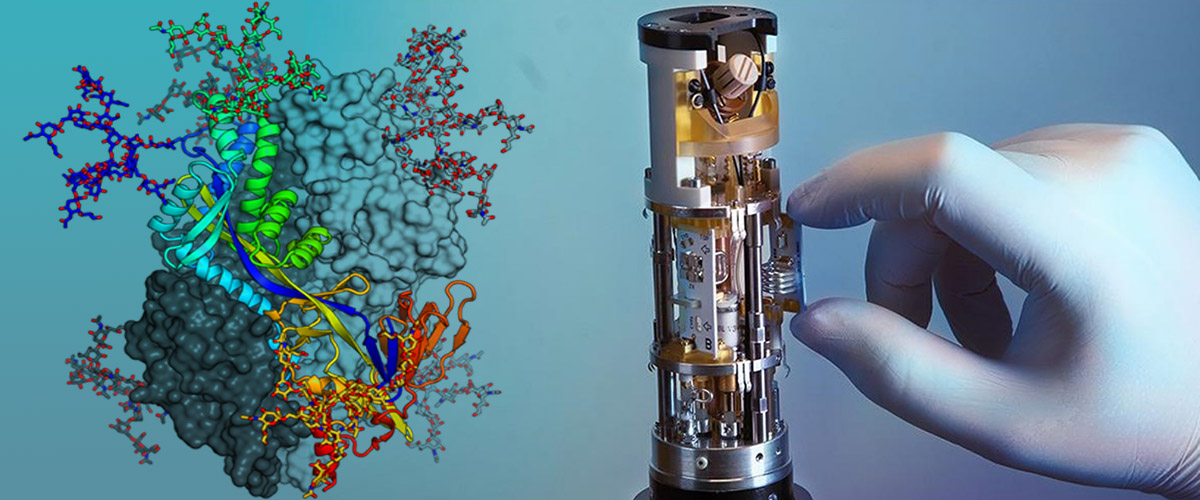

In addition to its ultra-small printing capabilities, the NanoOne Bio is uniquely capable of building biological structures at the nano scale, mimicking the arrangement and features of natural tissue.

"Our tool uses a process called multiphoton polymerization to form 3D structures and this system is capable of doing so in the presence of living cells," said Erika Bechtold, Vice President of U.S. Operations for UpNano, the maker of the NanoOne Bio. "We are printing a biological material around the cells. So, you can create very specifically tailored structures to study your cells more accurately in 3D."

The machine is able to build a blood vessel structure, or vasculature, and includes a full incubation unit that mimics the physiological conditions needed to keep cells alive and functioning normally during research. This will help researchers create things like artificial livers and other mini organs for drug testing.

"Being able to accurately simulate nanoflows and create true 3D microvasculature models has been a big challenge for bioengineers" said Bechtold. "It's one promising way our tool can help expand what's possible in micro and nano-scale biomedical engineering."

Ali and his MagLab and FAMU-FSU College of Engineering research team are also excited about the printer's potential for development of nanorobots — a cornerstone of their research portfolio. Their nanorobots are not the boxy metal bug-looking creatures you might be picturing from science fiction movies. Rather these specialized microscopic robots are engineered from bacteria or other natural cells combined with nonbiological materials like magnetic nanoparticles or synthetic molecules. Scientists can then use magnetic fields, sound waves, or light to control the cells.

Nanorobots are being studied for use in a wide range of health applications, including targeted drug delivery, precision biopsy, and clot-busting or plaque removal from arteries.

"One day we'll have these robots in our bodies, moving around fixing things, like the Fantastic Voyage. That's the ultimate goal," Ali said. "And we can make them out of sugar, or something like that. So, you don't have to worry about it staying in the body, it will just naturally degrade."

Ali partnered with NanoOne Bio for this 3D printer with funding from the Department of Defense. The Pentagon is supporting the research in hopes of improving systems for sensing environmental threats to the armed forces. Sophisticated mini sensors made of 3D printed biofilms, for example, could alert soldiers about biological or chemical hazards.

Because of the printer's unique capabilities, Ali expects it will draw interest from scientists around the U.S. He is anticipating new collaborations harnessing the nano-scale environment.

"A lot of these ideas are very long-term goals. But we're excited about the possibilities," Ali said.

"I see this as the start of something much bigger," Bechtold added about the first NanoOne Bio in the U.S. "Helping Dr. Ali and his team be successful means we all win as they continue to move the field forward and push the envelope of what’s possible today."