What did scientists discover?

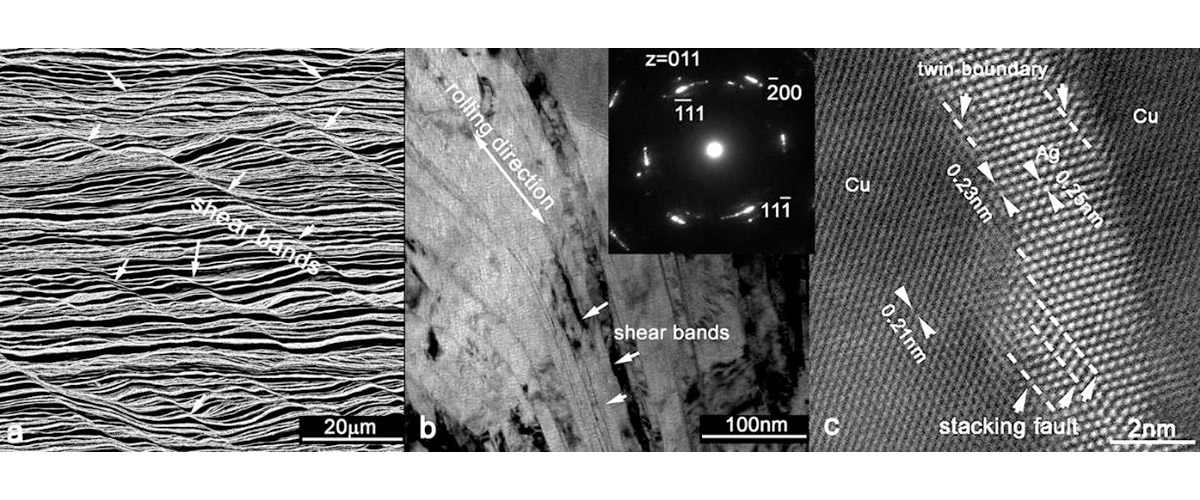

MagLab researchers studied the strain-hardening behavior of high-strength copper silver sheets by comparing overall and local stress-strain curves. They found that while both longitudinal and transverse samples showed overall softening, regions with highly strained slip bands displayed significant local strain-hardening in transverse samples and moderate strain-softening in longitudinal ones. This difference in localized plasticity caused the conductors to show overall anisotropic behavior.

Why is this important?

To maintain our high-field magnets, we need a constant supply of conductors that must pass strict quality checks. This work also has impact beyond high field magnets since Cu-Ag conductors can be used in advanced electronics, electrical and power grid industries, and aerospace and defense . Research on Cu-Ag conductors by Pimentel, Wu, Xin, and others was recognized at the 2024 Microscopy and Microanalyses conference, attended by 2,341 researchers. This work was one of only 15 to receive the "2024 M&M Student & Postdoctoral Scholar Award."

Who did the research?

R. Niu 1, V. Toplosky 1, H.L.S. Matos Pimentel 1, Y. Xin 1, J. Toth 1, and K. Han1

1Florida State University, National MagLab

Why did they need the MagLab?

The MagLab has unique facilities for characterizing materials, from the atomic level to full conductor size. It offers advanced mechanical testing to analyze strain in two dimensions and high-resolution microscopes to study material deformation. The lab also benefits from the expertise of its metallurgists and materials scientists.

Details for scientists

- View or download the expert-level Science Highlight, High Strength Copper-Silver Conductors for Magnets

- Read the full-length publication, Pockets of strain-softening and strain-hardening in high-strength Cu-24wt%Ag sheets, in Journal of Materials Science

- Read the full-length publication, Internal Stress in High-Strength CuAg Conductor, in IEEE Transactions on Applied Superconductivity

Funding

This research was funded by the following grants: K. M. Amm (NSF DMR-2128556)

For more information, contact Tom Painter.