What is the finding

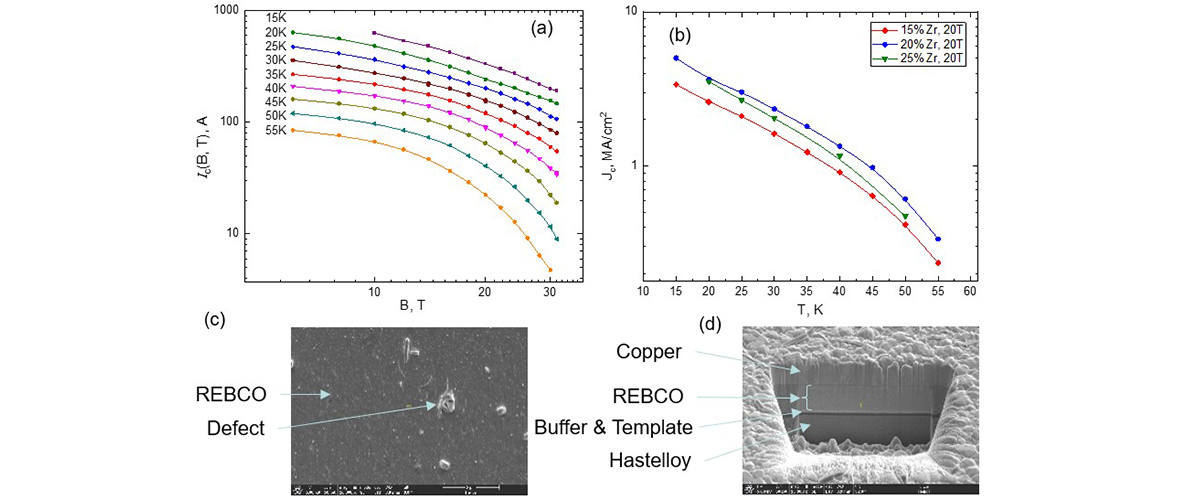

Creating strong, high-quality materials in long lengths without defects is difficult, but critically important for use in pulsed magnets at the MagLab. MagLab researchers found a way to improve the process by selecting the right chemistry and improving fabrication procedures. They successfully made Copper Chromium Zirconium (Cu-Cr-Zr) conductors up to 600 meters long with no defects, maintaining their strength at both room and extremely cold temperatures.

Why is this important?

Long-length conductors developed at the lab have led to major advancements, including increasing the number of pulses available in short-pulsed magnets, winding coils for a duplex magnet that generates over 75T, completing a key coil for the 60T continuous-wave magnet, and starting production of a 100T magnet coil without layer-to-layer joints. These longer conductors lower costs, reduce weak points, and improve overall performance.

Who did the research?

R. Niu1, V. Toplosky1, W. Starch1, T. Adkins1, I. Dixon1, J.W. Levitan1, J. Lu1, D. N. Nguyen2, and K. Han1

1Florida State University; 2Los Alamos National Laboratory

Why did they need the MagLab?

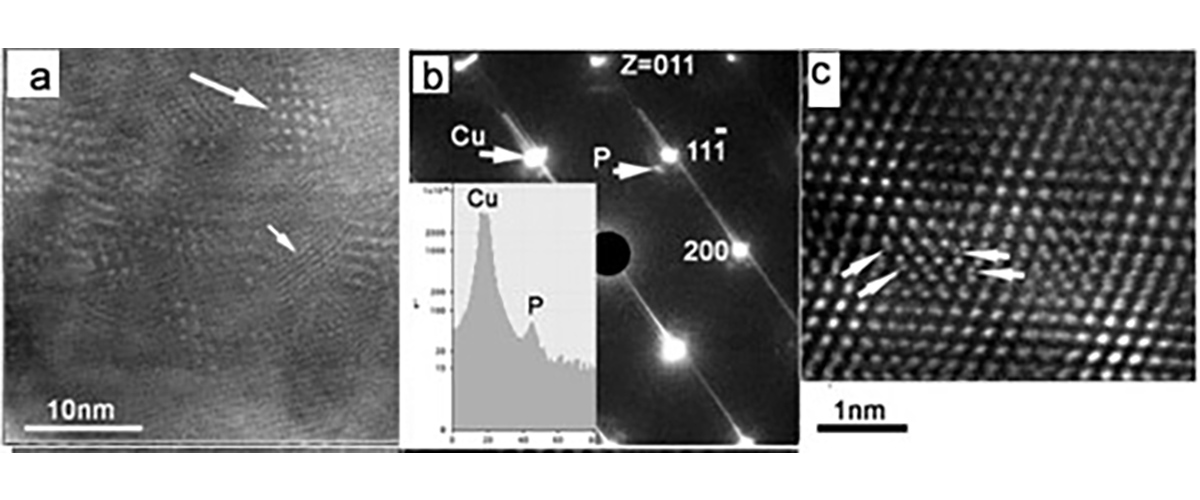

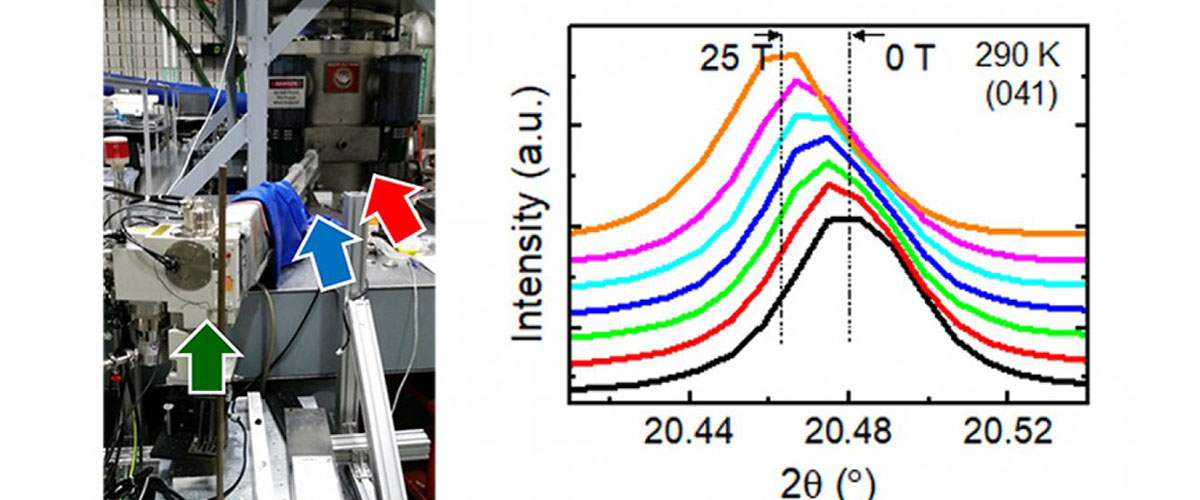

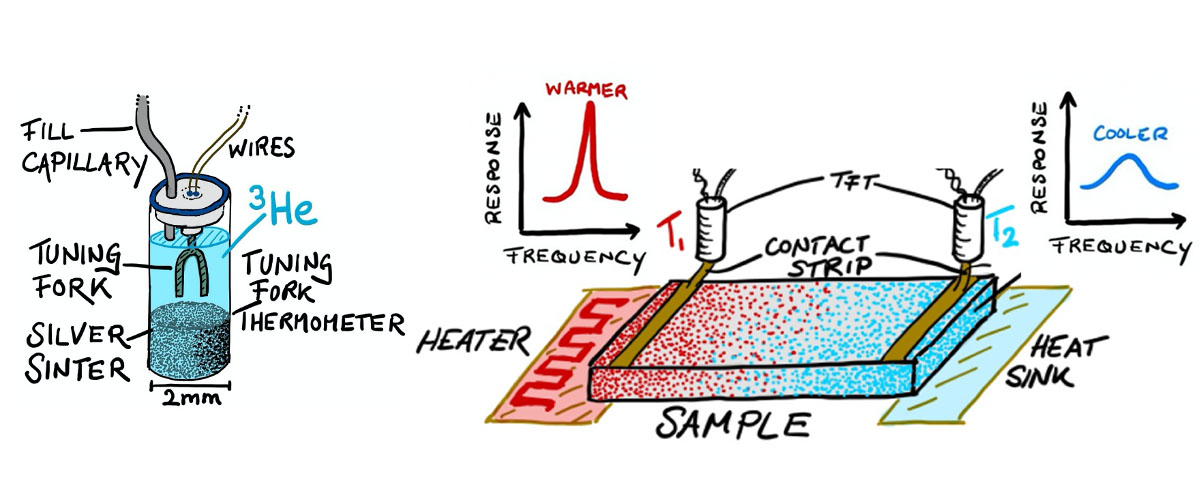

The MagLab has special tools to study conductor materials at every scale, from tiny atoms to full-sized wires. It has powerful microscopes, unique cold-temperature testing machines, and custom equipment for making and inspecting strong conductors. A team of experts, including metallurgists, engineers, and materials scientists, use these tools to develop and improve advanced materials.

Details for scientists

- View or download the expert-level Science Highlight, Development of long length, high strength conductors

- Read the full-length publication, Deformation induced precipitation in CuCrZr composites, in terials Science and Engineering A

Funding

This research was funded by the following grants: K. M. Amm (NSF DMR-2128556)

For more information, contact Tom Painter.