What did scientists discover?

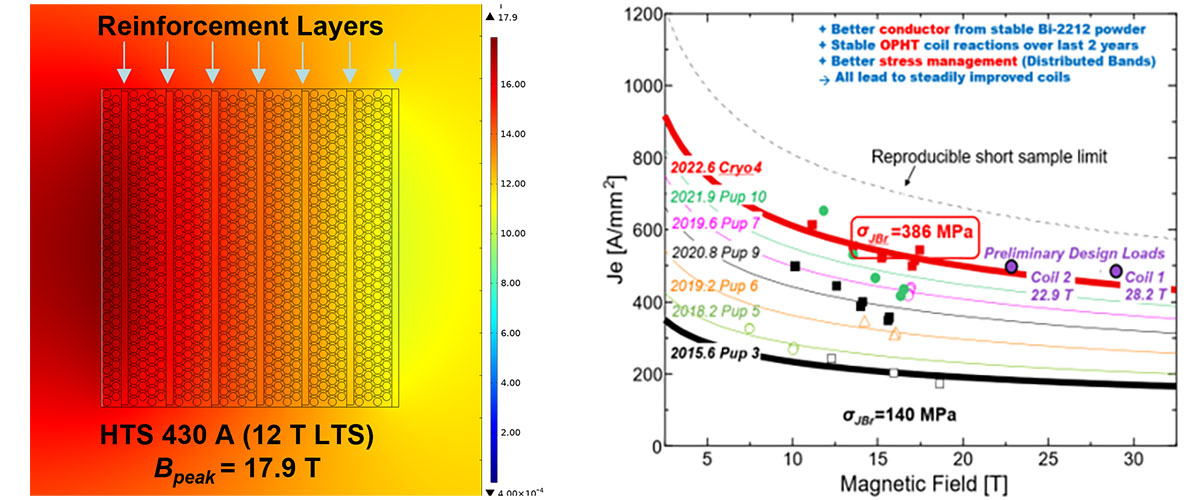

A 17.9T total magnetic field was achieved in an all superconducting magnet that contained a large coil of Bi-2212 (Bi2Sr2Ca1Cu2O8+x), a high temperature superconductor (HTS) with promising commercial applications. The Bi-2212 coil generated 5.9T in a 12T background field.

Why is this important?

Bi-2212 is unique among commercial HTS conductors as it is the only one available in multifilament, round wire, architecture. Its behavior is similar to Nb-Ti and Nb3Sn, the two superconductors that are common in low to mid-field commercial magnet systems. Bi-2212 can be cabled easily, and high-performance wire is regularly produced at lengths exceeding 1km. High field HTS magnets require mechanical reinforcement to operate reliably under high loads. To evaluate a specific reinforcement scheme laid out by numerical modeling, a coil was wound with that reinforcement and operated at high fields.

The coil withstood about twice the breaking stress of unreinforced Bi-2212 wire. This coil’s performance is a significant improvement and represents a milestone for the MagLab’s collaboration with Cryomagnetics LLC. It furthermore approaches the expected mechanical stress level in a proposed next generation 28T NMR magnet magnet without significant degradation.

Who did the research?

D.S. Davis1,2, Y. Kim1,2, U.P. Trociewitz1,2, L.D. Cooley1,2, D.C. Larbalestier1,2, S. Minter3

1Florida State University; 2Applied Superconductivity Center - MagLab; 3Cryomagnetics LLC.

Why did they need the MagLab?

The ASC, which joined the MagLab in 2006, plays a central role in the development of superconducting technology. The ASC owns and operates a 14T, 160mm large bore all superconducting magnet. This system has a very flexible layout, and besides producing high background field, it can be used for magnet tests requiring currents ranging from several hundreds of Amperes to 10kA. It is ideal for testing out the next generation of high field magnets and their technologies. In addition, the ASC is currently the only place to operate high-pressure furnaces that are required for the necessary heat-treatment of large Bi-2212 coils.

Details for scientists

- View or download the expert-level Science Highlight, An R&D Milestone for Bi-2212 High Temperature Superconducting Magnets

Funding

This research was funded by the following grants: S. Minter, US DOE flow through (PO#35917), D.C. Larbalestier (DE-SC0010421), G.S. Boebinger (NSF DMR-2128556)

For more information, contact Lance Cooley.