The renewed interest in Bi-2212 is because it is the only HTS cuprate that can be made as a round wire, which is the conductor geometry for magnet designers and builders prefer. As a round wire, it is also easy to cable, which is useful for high-field magnets. However, until 2014, Jc in round wire Bi-2212 was too low for practical applications. With its newly increased Jc, round-wire geometry, and high Hc2 (>100 T), its niche application will be in very-high-field magnets (>30 T) that are operated at 4.2 K.

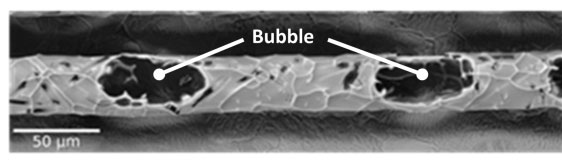

The breakthrough in 2014 was applying overpressure (OP) processing, which we originally developed for Bi-2223, another Bi-based HTS, that significantly increases Jc in long-length round wire. OP processing works by eliminating current-limiting bubbles in the wires. These bubbles are intrinsic in the wire due to the powder-in-tube (PIT) process used to make Bi-2212 round wire. Briefly, the PIT process is packing Bi-2212 powder in a Ag billet, drawing the billet into a wire, cutting and restacking sections of wire, and redrawing to make a multifilamentary wire. The Bi-2212 powder in the as-drawn wire is only about 60-70% dense, which means that the filaments contain 30-40% "empty" space between the particles of Bi-2212 powder that is filled with gas. The Bi-2212 wire has to be heat treated to make it superconducting. When the Bi-2212 powder melts, the gas agglomerates into big bubbles that occupy 30-40% of the overall filament volume and the larger bubbles can locally occupy entire filament cross-sections, as shown in Figure 1.

Fig.1 Single filament of Bi-2212 from a wire quenched during the heat treatment showing bubbles that formed when the Bi-2212 powder melted.

These bubbles do not disappear during the rest of the heat treatment, so they block super current in the fully-processed wire. OP processing works by applying a moderate isostatic pressure (100 bar) on the wire during the heat treatment. At elevated temperature, this compressive stress on the Ag sheath decreases the filament diameter, and thus the filament volume, until the volume of the filament cavity exactly matches the amount of Bi-2212 in the filament. Simply put, OP processing squeezes the bubbles out of the wire. Removing the bubbles significantly increases Jc – by as much as 6-7x compared to 1 bar processing. Ideally the gas in the PIT wire is pure oxygen, so it can diffuse through the Ag removing the gas in the bubbles.

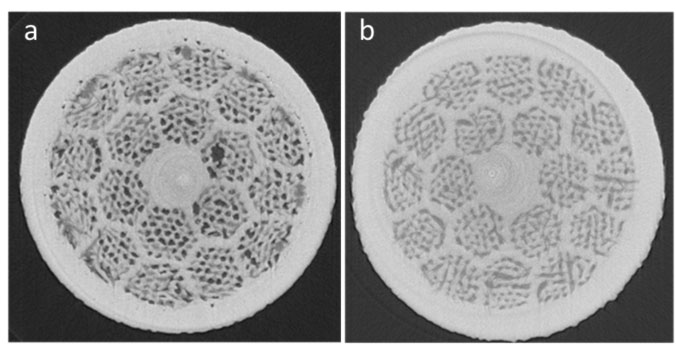

Figure 2 shows transverse cross sections of Bi-2212 wires that were processed with 1 bar of pressure (left) and with 100 bar of pressure (right). Comparing the images in Fig. 2, it is clear that OP processing eliminated the bubbles. Figure 3 shows our largest OP furnace, which has a hot zone that is 14 cm diam x 50 cm long.

Fig.2 Cross sections of fully-processed Bi-2212 round wire. (a) Wire that was processed in 1 bar of flowing oxygen. The black regions are bubbles. (b) Wire that was OP processed at 100 bar total pressure. Note that there are no bubbles. These cross sectional images were computed from x-ray tomographs collected by Scheuerlein et al.

Our activities are part of a wider Bi Strand and Cable Collaboration ("BSCCo") that combines our efforts with two national laboratories (FNAL and LBNL). The ultimate goal is to develop Bi-2212 wire technology so that it can be a viable material for building the next generation of high-field magnets for extending the energy and luminosity frontier of High Energy Physics and for high-field NMRs at the MagLab.

To make these goals possible we must understand this superconductor all the way from the materials science that underlies the superconducting properties to designing, fabricating, and testing demonstration coils. At the fundamental materials level we strive to understand the intrisic and extrinsic properties resulting from thermal processing with the development of electromagnetic properties of Bi-2212, and how super current crosses grain boundaries in Bi-2212. We are also designing and building NMR solenoid coils, where we explore the synergy between magnet design, coil winding, heat treatment, and coil performance.

Recent publications

Kametani et al., "Bubble formation within filaments of melt-processed Bi-2212 wires and its strongly negative effect on the critical current density", Superconductor Science and Technology 2011, 24 (7), 075009 (7 pp.). Read online …

In this study, we examined Bi-2212 wire processed in 1 bar of flowing oxygen, using a variety of techniques to investigate bubbles in Bi-2212 round wire. We showed that the bubbles that form in Bi-2212 wires during the heat treatment are still present in fully-processed wire. During cooling grains of 2212 can grow across the bubbles, which divides the big bubbles into many small bubbles. Because the bubbles in fully-processed wires are small and therefore hard to see using optical microscopy and SEM, they were not recognized as the major current limiting mechanism in Bi-2212 round wire. This paper identified the important negative role of bubbles on Jc and shifted the emphasis of subsequent research to investigate methods to remove these bubbles.

Larbalestier et al., "Isotropic round-wire multifilament cuprate superconductor for generation of magnetic fields above 30 T", Nature Materials 2014, 13 (4), 375-381. Read online …

This paper shows that overpressure (OP) processing eliminates bubbles in Bi-2212 round wires. This increased Jc about 6x compared to short, closed end samples to values, reaching Jc values that are useable for high-field magnets. OP processing is a derivative of hot isostatic pressing (HIP). OP processing applies a total pressure up to 100 bar using an Ar/O2 gas mixture. The Ar presses on the Ag sheath whereas the oxygen, which can diffuse through the Ag and sets the thermodynamic conditions needed to form Bi-2212. The O2 content is selected so that the oxygen partial pressure is 1 bar for the OP heat treatment. OP processing can be used to fabricate wind-and-react Bi-2212 coils.

For more information contact Eric Hellstrom.