Schematic

| Thumbnail View | Image Link | Description |

|---|---|---|

|

726KB - JPG |

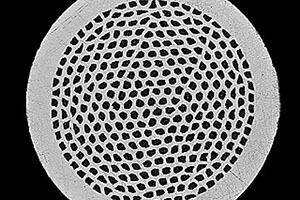

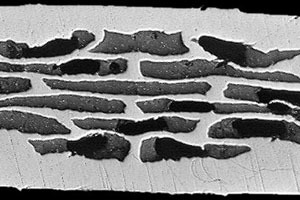

Expanded view of cross-section shown on the cover of Nature Materials. High density Bi-2212 filament macrostructure produced by the over-pressure (OP) technique developed at the Applied Superconductivity Center. The OP process almost eliminates the porosity that previously limited the transport critical current in Bi-2212 strands. This breakthrough will allow us to build the next generation of >30 T superconducting magnets using these round-wire multifilamentary wires. A higher magnification image was used for the cover of Nature Materials, March 2014 - see Larbalestier et al. Nature Materials: doi: 10.1038/nmat3887. |

|

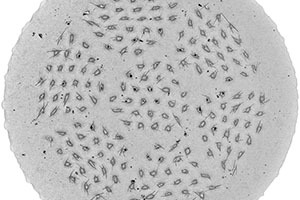

1027x991 370KB - JPG | One of the strengths of the Bi-2212 high-temperature superconductors is its ability to be made in long lengths of round-wires, this 27x7 filament composite was fabricated by OST and heat treated at the Applied Superconductivity Center using the over-pressure process (100 bar). SEM Image of polished cross-section by Jianyi Jiang. |

|

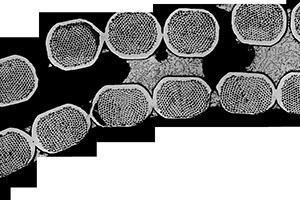

3967x1532 393KB - JPG | One of the strengths of the Bi-2212 high-temperature superconductors is its ability to be made in long lengths of multifilamentary cables, this one fabricated by Leszek R. Motowidlo, image by Jodi Reeves. |

|

526x394 57KB - JPG | One of the strengths of the Bi-2212 high-temperature superconductors is its ability to be made in long lengths of round-wires, this one fabricated by Leszek R. Motowidlo, image by Jodi Reeves. |

|

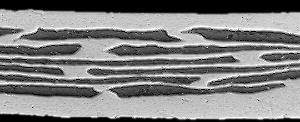

640x270 40KB - JPG |

One of the strengths of the Bi-2212 high-temperature superconductors is its ability to be made in long lengths of multifilamentary tapes, this one fabricated by Beate Lehndorff at CryoElectra GmbH. From Jodi Reeves, et. al. 1999. Effects of Overpressure Processing on Critical Current and Porosity in Bi-2212 Multifilamentary Wires with Various Geometries, et. al. 1999. Effects of Overpressure Processing on Critical Current and Porosity in Bi-2212 Multifilamentary Wires with Various Geometries, in IEEE Transactions on Applied Superconductivity: doi: 10.1109/77.784814. |

|

640x1220 19KB - JPG |

Bi-2212 high-temperature superconductor multifilamentary tape, this one fabricated by Beate Lehndorff at CryoElectra GmbH. From Jodi Reeves, et. al. 1999. Effects of Overpressure Processing on Critical Current and Porosity in Bi-2212 Multifilamentary Wires with Various Geometries, in IEEE Transactions on Applied Superconductivity: doi: 10.1109/77.784814. |

|

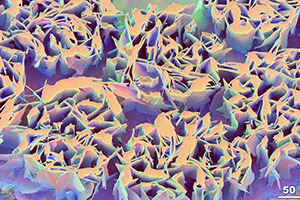

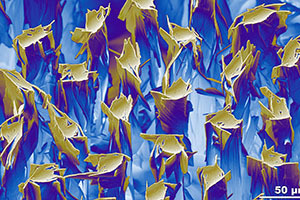

1929x1080 594KB - JPG | HTS: Bi-2212 filament structure revealed by etching away Ag matrix, This high density Bi-2212 filament macrostructure was produced by the over-pressure (OP) technique developed at the Applied Superconductivity Center. For this image the Ag matrix was etched down from a polished cross-section and imaged in a FESEM by Maxime Matras (color processing by Peter J. Lee). |

Powerpoints and Animations

| Thumbnail View | Image Link | Description |

|---|---|---|

|

3.3MB - PPTX | Animated zoom into etched Bi-2212 strand cross-section Transverse cross section of a 2212 round wire with 7 bundles of 27 filaments manufactured by OST. The wire has been heat treated at 100 atm over-pressure to densify the microstructure - see Larbalestier et al. Nature Materials: doi: 10.1038/nmat3887. The silver matrix has been etched down to reveal the sub-surface structure. FESEM images by Maxime Matras and Jianyi Jiang. View Powerpoint "smoothzoom" animation technique explained. |

|

3.3MB - PPTX | Animated panorama of the Grain/GB structure in a Bi-2212 filament The HTS superconductor Bi-2212 has the unique grain structure; 2-dimensional confinement by the filament structure makes the plate-like Bi2212 grains quasi-textured and the out-of-plane misorientation along the filament direction is ~±15°. In this very wide panorama we show OIM derived crystallographic orientations along a Bi-2212 filament. This animation was first shown in an invited talk by Fumitake Kametani at EUCAS 2013. The Powerpoint slide-transition technique used here is based on that developed by Troy Chollar ("The Powerpoint Blog"). Note: Instead of the "Wipe" transition we used "Push" and our animated intervals are 10" not 10.5". |

Video

Animated zoom into etched Bi-2212 strand sub-element cross-section-- Transverse cross section of a 2212 round wire with 7 bundles of 27 filaments manufactured by OST. The wire has been heat treated at 100 atm over-pressure to densify the microstructure - see Larbalestier et al. Nature Materials: doi: 10.1038/nmat3887. The silver matrix has been etched down to reveal the sub-surface structure. FESEM images by Maxime Matras and Jianyi Jiang.