There's nothing like a good, old-fashioned race to heat things up. And that's exactly what's happening across the world as engineers and scientists crunch data, test materials and assemble prototypes. Their goal: Find the best way to turn high-temperature superconductors (HTS) into world-record magnets.

To enable new science (see the accompanying story, Fields of Dreams), teams in the U.S., Asia and Europe are developing HTS technologies for research magnets, particle physics and other applications. At CERN, for example, planning is underway to build a larger Large Hadron Collider that would be almost four times as long as the existing collider and require thousands of superconducting magnets. HTS materials can also be used to build magnets for X-ray and neutron scattering experiments and even to study dark matter.

In the U.S., a race within a race began this year at the National High Magnetic Field Laboratory, where leaders are convinced HTS materials will boost magnets to the next level. What they aren't sure about yet is which HTS basket to put their eggs into.

Luckily, the lab houses a diverse group of HTS experts. So, funded by a $4.2 million grant from the National Science Foundation, they have formed four teams, each tasked with developing, in parallel, a different HTS design. In the end, one will be chosen to wind coils for a planned 40-tesla magnet that would pave the way for the next generation of high-field hybrid and superconducting magnets. These new instruments could help revolutionize the fields of particle physics, nuclear magnetic resonance (NMR) and magnetic resonance imaging (MRI).

The HTS super-contenders include two made from bismuth strontium calcium copper oxide, or BSCCO, and two from rare-earth barium copper oxide, or REBCO.

Why the four-flanked attack?

"No one conductor is the perfect package," explained Lance Cooley, director of the National MagLab's Applied Superconductivity Center (ASC).

The question is, which will check the most boxes in terms of cost, safety, reliability, material strength, field quality, resilience and ease of use?

One thing is certain: A long, twisting and potholed path lies ahead.

High and Mighty

Scientists have been studying stuff inside electromagnets for more than a century. So why do they need new materials to make them?

The building blocks they've used until now are copper alloys for resistive magnets, niobium-tin (NbSn) and niobium-titanium (NbTi) for low-temperature superconducting magnets. Both approaches face limitations preventing them from reaching fields much higher than they do today (about 41 teslas for resistive magnets and 24 teslas for low-temperature superconducting magnets).

Those fields wouldn't even make HTS break a sweat — at least theoretically.

Discovered three decades ago, high-temperature superconductors, as their name suggests, can operate at less frigid temperatures than their low-temp cousins. More to the point for magnet makers, they can also keep working well beyond 24 teslas. Some may operate upward of 50 teslas, according to David Larbalestier, chief materials scientist at the National MagLab, and have the potential to smash a huge magnetic field barrier that has been holding scientists back.

As the next step to realizing those ultra-high fields, engineers at the MagLab must first finish their HTS homework.

"No magnet is ever better than its conductors," cautioned Larbalestier. "You better understand those conductors, their defects and how they operate under the very intense stress and energy density conditions of an ultra-high-field magnet."

Which brings us back to our race: Ready, set — and they're off!

"A sleek frontrunner

And already the slim, trim, "no-insulation" (NI) REBCO has bounded into the lead.

This fleet-footed frontrunner already has a major coup to its credit: In 2017, it broke the world record for an HTS coil operating inside a resistive magnet. Its 14.3-tesla field, combined with a resistive field of 31.2 teslas, generated 45.5 teslas.

Traditionally, magnet makers weave insulators between the conducting turns to direct the current efficiently. But the clever NI design jettisons the insulation as a strategy to protect the magnet from a quench.

Quenches are to magnets what collisions are to motorists: Nobody likes them, and they may never happen, but you had better engineer for one, just in case.

Both quenches and car wrecks happen when a lot of energy is forced to come to a sudden, unexpected stop. Quenches occur when, perhaps due to a tiny imperfection, a conductor warms up enough to lose its superconducting property and reverts to normal electricity.

The result isn't as dramatic as a car crash. But when the electricity changes, so does the magnetic field, which has been storing a lot of energy. Without the right safeguards, all that energy will dump into that one failed section of the HTS coil, damaging, or even ruining, the whole thing.

You look at no-insulation and you think, 'Yeah, that's really cool — if you could pull it off.'

You can't guarantee against quenches, but you can control them. Conventional, insulated superconducting magnets do this with built-in heaters and copper that acts as a kind of back-up system for current. As soon as a quench starts somewhere in the coil, the heaters rapidly warm up the rest of it so that the whole thing stops superconducting. Then the copper picks up the current until the magnet is ramped down, protecting the coil from serious damage.

It's a lot of trouble to go to, but absolutely necessary — if the magnet is insulated. But if there's no insulation constricting the current to a specific path, it will just reroute itself to avoid the trouble spot and keep on superconducting. Because you don't need all that copper as a back-up system, you end up with a smaller magnet that experiences less mechanical stress and requires less reinforcing material.

The result is a compact coil that more than doubles the magnetic field–generating power of the previous record and a current density that outperforms the other HTS materials in this race.

"Superconductors are expensive," said Cooley, "so the more current density you can get, the less conductor you need to make the magnet you want."

Unfortunately, "no insulation" does not mean "no aggravation." Because current travels anywhere it wants around an NI coil, it is harder to predict the mechanical forces it will generate, and it’s harder for scientists running experiments to fine-tune the magnet’s field.

All in all, it's a promising technology: Even engineers backing other candidates have to admit NI REBCO has a lot going for it.

"You look at no-insulation and you think, 'Yeah, that's really cool — if you could pull it off,'" said Scott Marshall, lead engineer from a competing HTS group.

Taking the heat — and the pressure

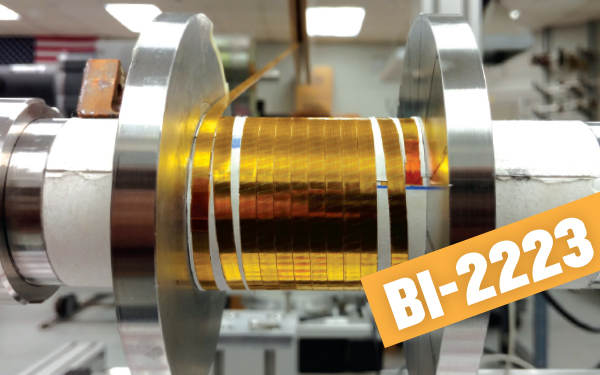

Supporters of rival bismuth-2212 (one of the two candidates from the BSCCO family) hope they will be the ones pulling it off. And, boy, the pressure's on!

Luckily, Bi-2212 can take it — up to 1,500 pounds per square inch of it — and some high heat, to boot. In fact, in order to work, these coils require that brutal treatment (called overpressure processing) to activate their superconducting properties.

Clearly, Bi-2212 is one tough contender, and promising for the type of magnets used in particle accelerators.

"In the accelerator magnet community, it's absolutely a game changer," said Cooley, who is working with Lawrence Berkeley National Laboratory to develop this technology. "It's a round wire, so you make a cable. Once you make a cable, you have the ability to use high currents."

The operative word there: "round."

In the accelerator magnet community, it's absolutely a game changer.

Round conductors are actually not the norm in the realm of HTS. For various reasons, neither REBCO nor Bi-2223 (the second bismuth-based compound in this race) are shaped into a round wire, though engineers would if they could and may one day get there. But for now, they’re manufactured as tapes, tricky for winding magnet coils because they’re anisotropic: They behave differently in a magnetic field depending on the orientation.

So, extra points to Bi-2212 for its roundness. Throw in a few more because it stops superconducting at a lower temperature than the other materials in this race, which could make quenches easier to manage.

Fabrication, though, is tricky: You can modify the coil before it goes in the furnace. But once it’s cooked, it's cooked; if it didn't bake just right, it's too late to fix it.

Luckily, MagLab experts continue to fine-tune overpressure processing, keeping Bi-2212 solidly in the running.

REBCO rivalry

But nipping at its heels is insulated REBCO — NI-REBCO's stockier big brother.

Like many big brothers, REBCO has something it lords over its scrawnier sibling: It has already matured into a full-fledged magnet that will be available to scientists in 2019.

Built with a combination of insulated REBCO coils and low-temperature superconductor (LTS) coils, the National MagLab's 32-tesla superconducting magnet racked up a remarkable world record in 2017 with a field a third stronger than any previous superconducting magnet. And it was no proof-of-concept prototype, like its younger, no-insulation sibling: It is designed and built for scientists to use.

"We have done far more than all of the other technologies combined," said Huub Weijers, project manager for the 32-tesla magnet. "So there's a big experience advantage."

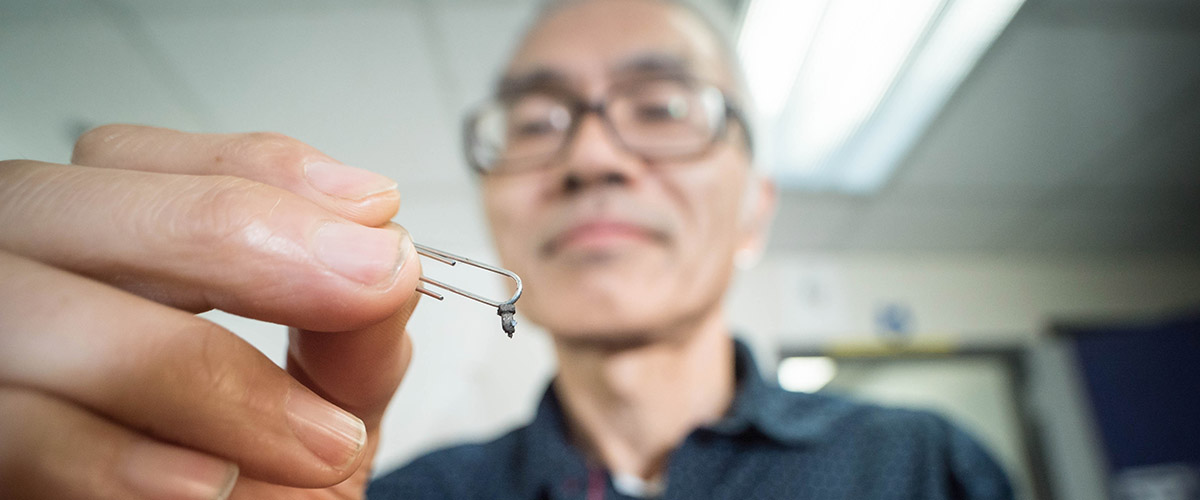

A decade in the making, the 32-tesla magnet has already provided scientists a wealth of data about insulated REBCO design. They have worked through lots of problems, like how to best join lengths of REBCO tape. Amazingly, each 50- to 100-meter-long section represents a single crystal, and engineers must carefully connect them to keep the current flowing smoothly.

We have done far more than all of the other technologies combined. So there's a big experience advantage.

But engineers face an even bigger hurdle in scaling the design up to the 40-tesla range: protecting the magnet from quenching.

If the LTS coil were to quench, it would damage the adjacent HTS coil by straining the material. The 32-tesla magnet is designed to prevent that scenario by inducing a controlled quench in the HTS coil using a large battery bank to heat up the coil. But scaling that strategy up to a 40-tesla magnet would require an impractically huge battery bank.

Weijers thinks there's another way to tackle that problem: re-engineer the REBCO tape. The existing version, he said, is actually too good, with a current density far exceeding requirements.

"It's like having a jet engine on a crop duster," Weijers said.

Limiting that current will reduce the amount of energy required to manage potential quenches, he said, keeping insulated REBCO in the running.

Don't discount the underdog

Last but not least, bringing up the rear of this fab field of four, is Bi-2223.

Some consider the compound a long shot for 40-T material because of its lowest-in-class current density. So you'd have to use more of the stuff, resulting in a bulkier, costlier instrument.

"It might not be in the range of fields that we're interested in getting," said ASC Director Cooley. "Thirty teslas, maybe."

Still, the material has advanced to the finals for a reason: Manufacturer Sumitomo Electric has upped the product's current density and improved its strength with a layer of nickel alloy. Plus, the magnet would be relatively easy to build: Buy the tape and wind the coils — no need for fancy cooking or trailblazing design. And by virtue of the conductor's filamentary tape structure, it produces (like its bismuth brother, 2212) a field that is precise, controllable and predictable. In fact, several NMR magnets have already been built with 2223.

This … might actually turn out to be the most reliable magnet we can build.

And the price, at least for now, is right. Commercially available for more than two decades, Bi-2223 goes for $30 a meter — half as much as REBCO.

It's definitely too soon to count this underdog out, said engineer Marshall, head of Team 2223.

"It could be that this stuff, which is the most mature conductor technology and tried and true, might actually turn out to be the most reliable magnet we can build," he said.

And the winner will be ...

Drumroll please: You! Me! All of us! That's how the scientific process works. Research, fabricate, test, measure, repeat: The data will determine the winner.

In fact, argues MagLab scientist Hongyu Bai, manager for the 40-tesla project, in this race, there are no losers.

"Different technologies have different advantages," Bai said. "If they are not selected for the 40-T magnet, they could be a good choice for other applications."

For example, like solving the mystery of dark matter and dark energy, which hog up most of our universe. One theory says they're made up of axions, hypothetical particles that high-field magnets could help detect.

"We're talking to the axion community about building magnets like that," said Mark Bird, director of magnet science and technology at the National MagLab, "and they would require high-temperature superconductors."

Each of these conductors will find its niche, whether that's solving cosmological puzzles, transmitting electricity over long distances, powering particle accelerators or generating high-resolution MRI images. However this particular race shakes out, it will be a very big win for science.

Story by Kristen Coyne. Story science advisor: Huub Weijers.