What did scientists discover?

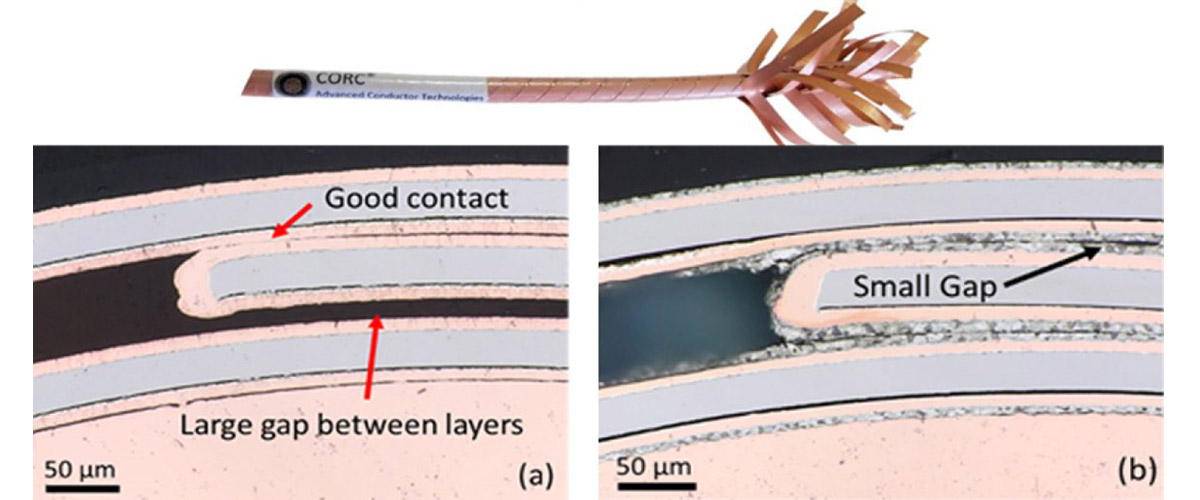

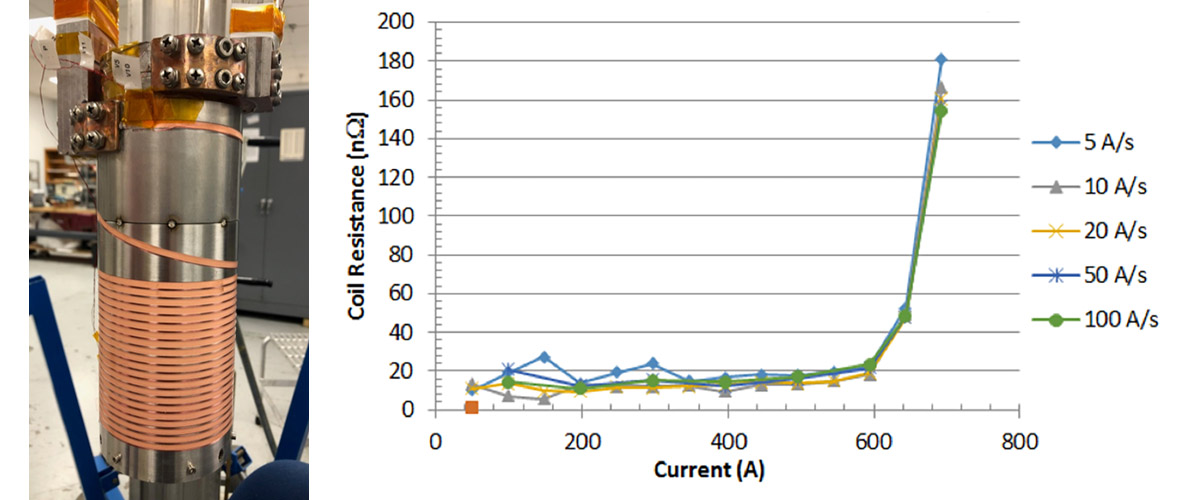

Recent tests of the MagLab’s Integrated Coil Form (ICF) technology suggest that high-temperature superconducting (HTS) REBCO tape may enable simpler REBCO cables to be built and operate reliably than is possible with traditional low-temperature superconducting (LTS) cables.

Why is this important?

This work show that a compact, stacked-tape cable may be efficiently deployed in the extremely-well-reinforced ICF coil technology. This may play a central role in the MagLab’s quest to realize a 60T hybrid magnet, a national goal articulated in the 2005 COHMAG and 2013 MagSci reports issued by the National Academies of Science.

Who did the research?

Thomas Painter, Kwangmin Kim, Mike White, Robert Stanton

National MagLab, Florida State University

Why did this research need the MagLab?

The infrastructure and experienced staff at the MagLab were essential for conceiving and developing the ICF technology and building the test coils. The MagLab is unique in its collection of leading experts, not only in magnet materials science, but also in magnet design, fabrication and precision machining. The latest state of the art HTS tapes are extremely fragile. Knowledge and experience of mechanical design and winding practices developed in the MagLab’s 32T all-superconducting magnet were essential to building a damage-free ICF test coil.

Details for scientists

- View or download the expert-level Science Highlight, Integrated Coil Form Technology for Ultra High Magnetic Fields

Funding

This research was funded by the following grants: G.S. Boebinger (NSF DMR-1157490); T.A. Painter (EPSRC EP/R016615/1)

For more information, contact Mark Bird.

![Scientists studied the copper-based compound [Cu(pyrimidine)H2O4] SiF6 H2O. Repeating units of four copper ions (see above) create corkscrew-like chains with intriguing magnetic properties.](/media/ayslgnyz/june2019_emr_chiral_staggered_chain.jpg)