First, some background

Pulsed magnets are under such intense pressures when they are energized to high magnetic fields that they simply wear out after a certain number of pulses and must be replaced. The 100T Pulsed Magnet is the flagship magnet at the MagLab’s Pulsed Field Facility, holding the world record for non-destructive generation of a magnetic field by a pulsed magnet. The magnet has reached 100.75T, but is routinely operated at 92T to 95T to reduce the risk of the magnet wearing out.

What did scientists discover?

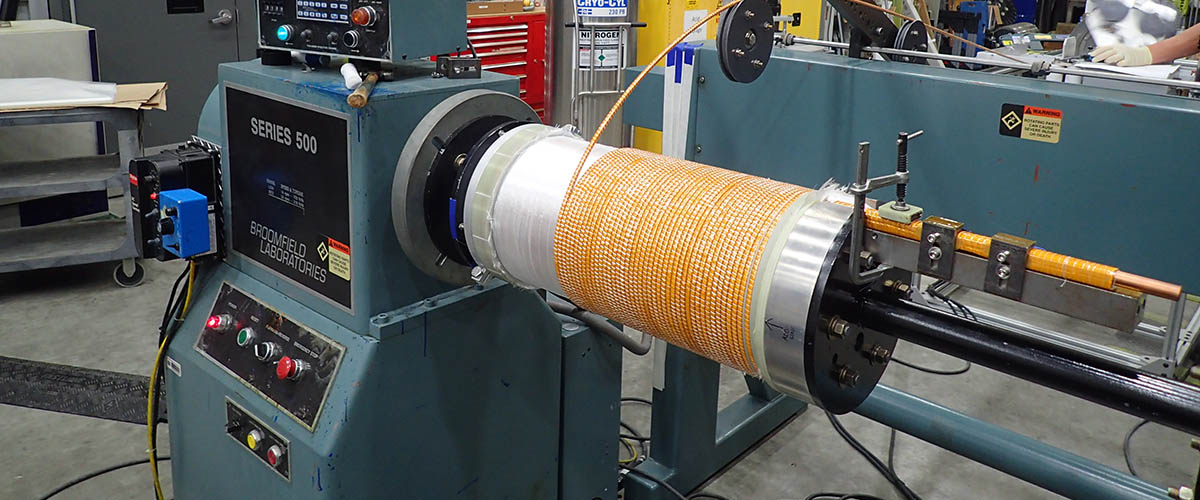

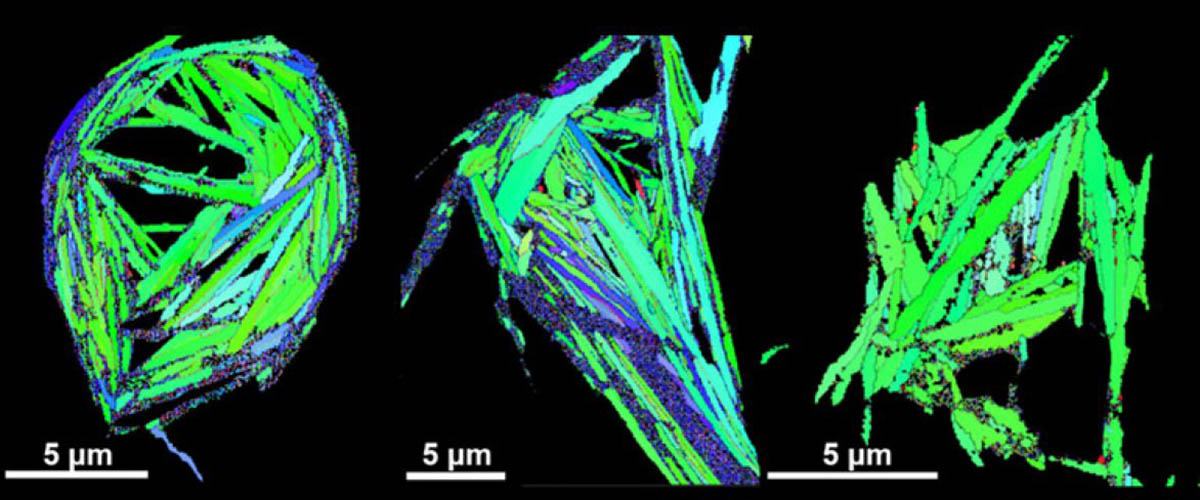

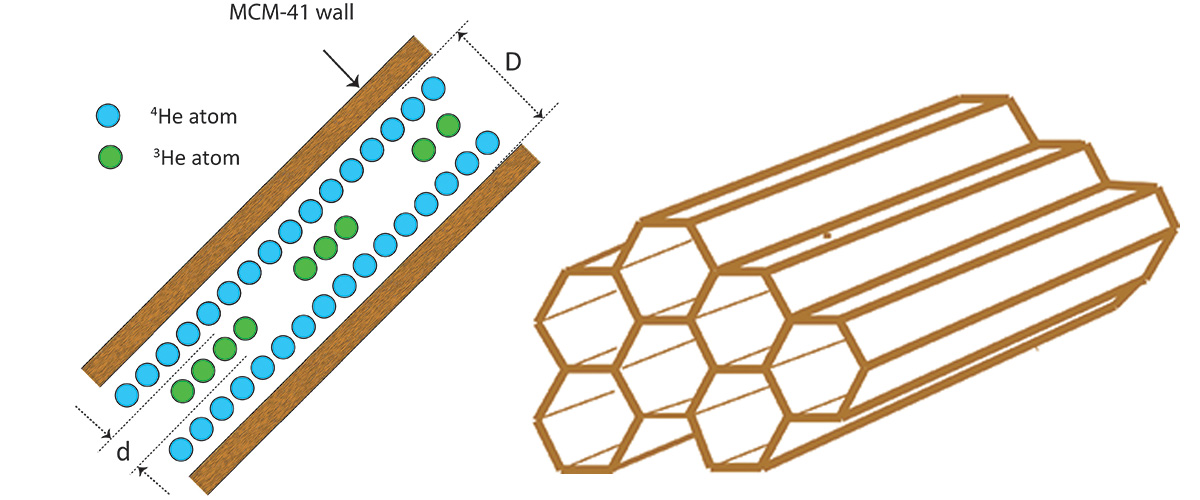

Recent advances in big-coil fabrication at the MagLab and an increased understanding of high strength materials has enabled in-house fabrication of outsert coils for the MagLab’s largest pulsed magnets. We expect that this in-house fabrication will enable more rigorous quality control during fabrication to improve the reliability and lifetime of the 100T Pulsed Magnet, such that coils can be replaced less frequently.

Why is this important?

The MagLab's users benefit from higher magnetic fields because they yield scientific discoveries. More reliable and stronger coils result in improved and extended magnet performance and, thus, greater access to higher fields.

Who did the research?

Iain Dixon1, Todd Adkins1, Ke Han1, Justin Deterding1, Don Richardson1, Robert Stanton1, Vince Toplosky1, Rongmei Niu1, Jun Lu1, Robert Goddard1, William Starch1, Doan Nguyen2

1National MagLab, Florida State University,Tallahassee FL 2National MagLab Pulsed Field Facility, Los Alamos National Laboratory, Los Alamos NM

Why did this research need the MagLab?

The MagLab leads the world in high-field magnet technology development and magnet engineering. Expertise developed from winding large superconducting coils has been coupled with pulsed magnet expertise to advance the state of the art for pulsed coil fabrication.

Details for scientists

- View or download the expert-level Science Highlight, In-House Fabrication of Outsert Coil 1 for the 100T Pulsed Magnet

- Read the full-length publication, Status and Development of Pulsed Magnets at the NHMFL Pulsed Field Facility, in IEEE Transactions on Applied Superconductivity

Funding

This research was funded by the following grants: G.S. Boebinger (NSF DMR-1157490, NSF DMR-1644779)

For more information, contact Mark Bird.